في مواجهة السوق العالمية التي تزداد تعقيدًا في عام 2025، هل تجد صعوبة أكبر من أي وقت مضى في العثور على المورد المثالي للأواني الزجاجية؟ كقائد مشتريات، لا شك أن حالة عدم اليقين في سلسلة التوريد، وارتفاع التكاليف، والطلب الملح على المنتجات المستدامة تملأ كل قرار شراء بالضغوط.

لاختيار أفضل مورد للأواني الزجاجية عالية البورسليكات في عام 2025، تحتاج إلى استراتيجية شاملة: تحقق بدقة من شهادات السلامة الدولية 1{#ref-1}وتقييم خيارات التخصيص المرنة والاستدامة، والتأكد من ميزات المنتج مثل مقاومة الصدمات الحرارية، والتدقيق العميق في قدرتها الإنتاجية و مرونة سلسلة التوريد 2{#ref-2}.

بصفتي مؤسس شركة PYGLASS، فقد انخرطت بعمق في صناعة الزجاج لأكثر من 15 عامًا. وخلال هذا الوقت، عملت مع المئات من مديري المشتريات مثلك تمامًا وشهدت نجاحات وإخفاقات لا حصر لها. لقد شاهدت الدرس المؤلم المتمثل في اختيار مورد رديء مقابل بضعة سنتات في السعر، فقط لكي تكون الشحنة بأكملها غير قابلة للبيع. إن هدفي من كتابة هذا الدليل هو مشاركة تجربتي من منظور الشركة المصنعة من الداخل، لمساعدتك على تجنب المزالق الشائعة والعثور على شريك طويل الأجل يمكنه حقًا خلق قيمة لعلامتك التجارية.

ما هي شهادات السلامة التي يجب أن يحصل عليها المورد للوفاء بالمعايير الدولية؟

"كيف يمكنني التأكد من أن منتجاتك متوافقة وآمنة في بلدي؟ هذا هو السؤال الأكثر شيوعًا الذي أتلقاه من العملاء الجدد، وهو السؤال الأهم الذي يجب أن تطرحه. في عام 2025، سيصبح التدقيق في سلامة المنتجات أكثر صرامة.

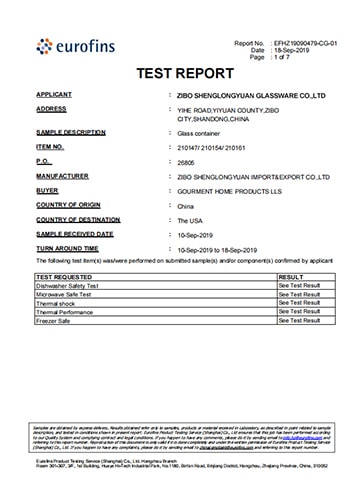

لضمان استيفاء الأواني الزجاجية الخاصة بك للمعايير الدولية، يجب عليك العثور على مورد يمكنه تقديم وثائق اعتماد كاملة لإدارة الأغذية والعقاقير (بالنسبة للولايات المتحدة الأمريكية)، و LFGB (بالنسبة لألمانيا والاتحاد الأوروبي)، و DGCCRF (بالنسبة لفرنسا). هذه هي جوازات السفر الأساسية لدخول الأسواق الرئيسية، ولا يمكن أن ينقصها أي منها.

كشركة مصنعة تقوم بشحن المنتجات على مستوى العالم، فإن الامتثال هو حجر الأساس لأعمالنا. مثلك تماماً، لا يمكننا تحمل مخاطر احتجاز شحنة من قبل الجمارك أو رفضها من قبل تجار التجزئة. ولهذا السبب نستثمر بشكل استباقي أموالاً طائلة كل عام في اختبار المنتجات لضمان استيفائنا لجميع المعايير الدولية. إذا كان المورد مراوغاً عندما تطلب منه تقديم تقارير الشهادة، أو إذا كان بإمكانه فقط تقديم مستند منتهي الصلاحية وغير واضح، فهذا يعد علامة حمراء قاطعة. سيقوم الشريك المحترف بمناقشة لوائح السوق المستهدفة معك بشكل استباقي لضمان بقاء منتجاتك متوافقة لسنوات قادمة.

الشهادات الأساسية: الضمانات الأساسية التي يجب أن نقدمها

بغض النظر عن تغيرات السوق، فإن بعض شهادات سلامة الأغذية الأساسية غير قابلة للتفاوض بالنسبة لنا كمورد. هذه هي العتبة الأولى لتقييمنا.

- إدارة الغذاء والدواء الأمريكية (FDA): وهذا شرط إلزامي لدخول منتجاتنا إلى السوق الأمريكية.

- LFGB (قانون الأغذية والسلع والأعلاف الألماني): نحن مصرون على اجتياز هذا "المعيار الذهبي" لسوق الاتحاد الأوروبي لأن اختباراته الصارمة تمثل بشكل أفضل التزامنا بالجودة العالية.

- المديرية العامة لسياسة المنافسة وشؤون المستهلكين ومكافحة الغش (DGCCRF): هذه شهادة أساسية يجب أن نقدمها عند خدمة عملائنا في فرنسا.

التطلع إلى عام 2025: اتجاهات جديدة ننصحك بمراقبتها

وبعيداً عن الشهادات التقليدية، أوصي مديري المشتريات ذوي التفكير المستقبلي بالاهتمام بالنقاط التالية وسؤال الموردين عنها

- إمكانية التتبع: يمكنك أن تسأل أحد الموردين "هل يمكنك تتبع مصدر المواد الخام الأساسية (مثل البوراكس) لهذه الدفعة من المنتجات؟ يجب أن يكون المصنع المُدار جيدًا قادرًا على القيام بذلك.

- التحقق الرقمي: في عام 2025، يمكنك طلب نسخ رقمية يمكن التحقق منها من الشهادات باستخدام رموز QR، والتي يمكن أن تمنع تزوير المستندات بشكل فعال.

- عمليات تدقيق المسؤولية الاجتماعية للشركات: أهمية عمليات التدقيق مثل BSCI 3{#ref-3} آخذة في النمو. الأمر لا يتعلق فقط بالإنتاج الأخلاقي؛ بل يتعلق بصورة علامتك التجارية. إن اختيار مورد مسؤول اجتماعياً هو أيضاً استثمار في قيمة علامتك التجارية.

| التصديق/التدقيق | النقاط الرئيسية التي يجب التركيز عليها | الأهمية في عام 2025 |

|---|---|---|

| إدارة الأغذية والعقاقير والطب البيطري والغابات والأغذية والزراعة | سلامة ملامسة الأغذية الأساسية | حاجز الدخول. وبدون ذلك، لا يمكن لمنتجات المورد أن تدخل الأسواق الرئيسية. |

| آيزو 9001 4{#ref-4} | نظام إدارة الجودة | ضمان الاتساق. يثبت أن المورد لديه نهج قائم على العمليات لمراقبة الجودة. |

| BSCI / SMETA | المسؤولية الاجتماعية والأخلاقية للشركات | خندق لسمعة علامتك التجارية. تجنب المخاطر المرتبطة بالأخبار السلبية حول قضايا العمل. |

| شهادات الاستدامة | المواد المعاد تدويرها والتغليف الخاص بمعايير السلامة الغذائية، إلخ. | محرك جديد لنمو السوق. يساعد منتجك على تلبية طلب المستهلكين على الخيارات الصديقة للبيئة. |

كيف يجب على المورد استخدام التخصيص لمساعدة علامتك التجارية على التميز؟

يأتي إلينا العديد من مديري المشتريات وهم يشعرون بالإرهاق. ويقولون إن "التخصيص" بالنسبة للعديد من المصانع لا يعني بالنسبة للعديد من المصانع أكثر من ختم شعار على منتج قياسي. ولكن في سوق المنتجات المتجانسة اليوم، هذا أبعد ما يكون عن الكفاية. نحن نعتقد أن التخصيص الحقيقي هو شراكة عميقة.

لجعل علامتك التجارية مميزة، تحتاج إلى عقد شراكة مع مورد يقدم خدمات متعمقة لتصنيع المعدات الأصلية/التصنيع حسب الطلب 5{#ref-5}. ولا يشمل ذلك طباعة الشعار على الغطاء فحسب، بل يشمل أيضاً تصميم العبوات الصديقة للبيئة وهياكل المنتجات المبتكرة وتصاميم الإكسسوارات الفريدة.

من من وجهة نظرنا، التخصيص هو العملية التي نجعل فيها رؤية علامتك التجارية تنبض بالحياة. يجب أن يعمل الشريك الحقيقي لتصنيع المعدات الأصلية/التصنيع حسب الطلب كامتداد لفريق تطوير منتجك. على سبيل المثال، عندما يطلب العميل فكرة "صديقة للبيئة"، فإننا لا نقترح فقط غطاءً من الخيزران. بل نناقش معك كيفية تحقيق التغليف "الخالي من البلاستيك"، وما إذا كان الورق يجب أن يكون معتمداً من مجلس رعاية الغابات (FSC)، وما إذا كان الحبر يمكن أن يكون حبراً صديقاً للبيئة يعتمد على الصويا. في PYGLASS، نقدم مجموعة واسعة من الخيارات بدءًا من الأغطية المصنوعة من الخيزران والبولي بروبيلين إلى تصميم العبوات الشامل، بهدف المساعدة في توصيل قصة علامتك التجارية بوضوح من خلال كل تفاصيل المنتج.

الأبعاد الجديدة للتخصيص في عام 2025

بصفتك شريكاً لك، نقترح عليك التفكير بشكل أعمق في التخصيص.

1. التخصيص الوظيفي المتعمق لوظائف المنتج (ODM)

يمكنك العمل مع فريقنا الهندسي لتطوير ميزات تحل مشاكل المستخدمين.

- تصميم التكديس المحسّن: إن التصميم الجيد للتكديس لا يوفر مساحة الخزانة للمستهلكين فحسب، بل يمكن أن يوفر لك أيضًا تكاليف شحن كبيرة.

- أغطية متعددة الوظائف: يمكننا المشاركة في تطوير أغطية مزودة بفتحات تهوية تعمل بالموجات الدقيقة، أو ميزات تتبع التاريخ، أو التوافق مع أجهزة تفريغ الهواء لزيادة قيمة المنتج.

- تركيبات معيارية: إن تصميم خطوط إنتاج بأحجام مختلفة يمكن دمجها وإقرانها يعزز بشكل كبير من تجربة المستخدم ونية الشراء.

2. حلول التغليف المستدامة

في عام 2025، لم يعد التغليف في عام 2025 يتعلق بحماية المنتج فحسب، بل أصبح انعكاساً مباشراً لالتزام العلامة التجارية بالبيئة.

- البدائل الخالية من البلاستيك: يمكنك أن تطلب من المورد الذي تتعامل معه توفير حلول صديقة للبيئة مثل الأشرطة اللاصقة الورقية أو حشوات نشا الذرة.

- تصميم بسيط: إن التصميم البسيط للتغليف باستخدام مادة واحدة (مثل ورق الكرافت) وطباعته بحبر صديق للبيئة لا يقلل من التكاليف فحسب، بل يكون أكثر جاذبية للمستهلكين المهتمين بالبيئة.

- شهادة FSC: الإصرار على استخدام ورق معتمد من FSC 6{#ref-6} هي الطريقة الأكثر مباشرة لتظهر للمستهلكين أن علامتك التجارية تدعم الإدارة المسؤولة للغابات.

| بُعد التخصيص | النهج التقليدي | استراتيجيتنا الموصى بها لعام 2025 |

|---|---|---|

| هوية العلامة التجارية | طباعة شعار على الغطاء | نقش بالليزر على الأغطية المصنوعة من الخيزران، باستخدام حبر صديق للبيئة، أو أكمام سيليكون مخصصة تحمل شعاراً. |

| وظائف المنتج | تقديم أحجام مختلفة | تطوير منتجات ذات أغطية قابلة للتكديس بشكل مثالي ومعيارية ومبتكرة. |

| تغليف المنتج | صناديق مغلفة بالألوان الكاملة | استخدام ورق معتمد من FSC وتصميم بسيط وحشوات خالية من البلاستيك. |

| تجربة المستخدم | بما في ذلك دليل التعليمات | طباعة رمز الاستجابة السريعة على العبوة لإرشاد المستخدمين إلى مقاطع فيديو للاستخدام/التنظيف أو تقديم وصفات. |

ما الميزات التي يجب أن أطلبها لحل مشاكل التسرب والكسر بشكل أساسي؟

كشركة مصنعة، ليس هناك ما هو أكثر إيلامًا بالنسبة لنا من سماعنا أن منتجات العميل تتلقى العديد من الشكاوى بسبب التسريبات والكسر. فكل مراجعة سلبية لا تضر فقط بعلامتك التجارية ولكن أيضاً بسمعتنا كمنتج. ولهذا السبب فإن سيطرتنا على المواد والتصميم تكاد تكون مهووسة.

لحل هذه المشاكل بشكل أساسي، نوصي بشدة بالإصرار على متطلبين أساسيين: أولاً، يجب أن تكون المادة الرئيسية زجاج البورسليكات العالي 7{#ref-7} لضمان مقاومته الممتازة للصدمات الحرارية؛ ثانيًا، يجب أن يكون الغطاء مزودًا بغطاء سميك وسهل الإزالة للتنظيف ومزودًا بسداد من السيليكون المخصص للطعام وآلية قفل آمنة من أربعة جوانب.

تذكرت تجربة أحد العملاء عندما جاءوا إلينا لأول مرة؛ وكان الدرس عميقًا. لتوفير بضع نقاط مئوية من التكلفة، فقد اختاروا موردًا يستخدم زجاجًا عاديًا من الجير الصودا. ونتيجة لذلك، وخلال فصل الشتاء الأول بعد إطلاق المنتج، انهالت الشكاوى على شركتهم خلال فصل الشتاء الأول بعد إطلاق المنتج، حيث انهالت الشكاوى على شركتهم بشأن تحطم أطباق الخبز في الأفران المسخنة مسبقًا، مما اضطرهم في النهاية إلى سحب المنتج على نطاق واسع. ومنذ ذلك الحين، أصبح "زجاج البورسليكات العالي" العنصر الأول غير القابل للتفاوض في قائمة مشترياتهم. وتعد قصتهم تذكيرًا دائمًا لنا بأنه بالنسبة للتفاصيل المهمة مثل الختم، يجب أن نتحقق منه مرارًا وتكرارًا للتأكد من أنه يحافظ على مرونته وقوة إحكامه بعد الاستخدام طويل الأمد. يجب أن يكون المنتج الممتاز مثاليًا في مجالات الأداء الأساسية هذه.

مصممة هندسيًا لتحقيق أداء فائق

تكمن وراء كل منتج يمنح المستخدمين راحة البال تفاصيل هندسية لا حصر لها نحرص كمصنعين على أن تكون وراء كل منتج يمنح المستخدمين راحة البال.

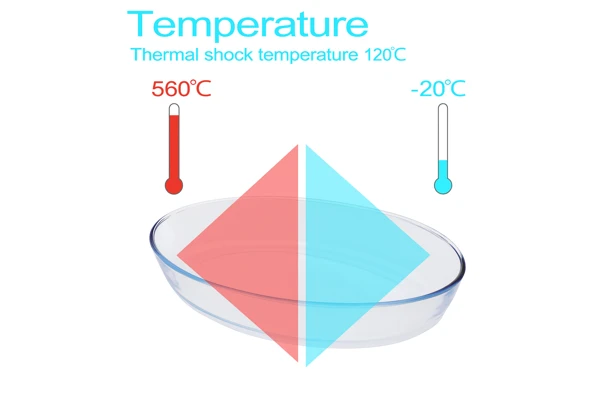

1. زجاج البورسليكات العالي: أساس الأمان الذي لا هوادة فيه

هذا هو حجر الزاوية في سلامة المنتج ومتانته، ونحن لا نساوم على ذلك أبداً.

- ممتاز حراري مقاومة الصدمات 8{#ref-8}: يمكنه تحمل اختلاف فوري في درجة الحرارة لا يقل عن 120 درجة مئوية (248 درجة فهرنهايت). هذا يعني أنه يمكن للمستخدمين أخذ وعاء زجاجي بأمان من الثلاجة ووضعه مباشرة في الميكروويف.

- ثبات كيميائي أعلى: لا يتفاعل مع الأطعمة الحمضية أو القلوية ولن يتفاعل مع الأطعمة الحمضية أو القلوية ولن يرشح المواد الضارة، مما يضمن المذاق الأصلي وسلامة الطعام.

- قوة بدنية أكبر: مقارنةً بالزجاج العادي، فهو أكثر مقاومة للخدوش والصدمات، مما يؤدي إلى إطالة عمر المنتج، وهو ما يتماشى أيضاً مع مفهوم الاستهلاك المستدام.

2. نظام الختم: تركيزنا من أجل روح مانعة للتسرب

يعتمد تسعون بالمائة من أداء إحكام غلق الحاوية على تصميم مانع التسرب ومشابك القفل.

- ختم من السيليكون المخصص للطعام: نحن نصرّ على استخدام سيليكون عالي الجودة من الدرجة الغذائية ليس فقط غير سام وعديم الرائحة ولكنه يقاوم التشوه والتقادم بعد الاستخدام طويل الأمد.

- تصميم "سهل الإزالة": صُممت أختامنا بحيث يمكن إزالتها بسهولة. وهذا أمر بالغ الأهمية للتنظيف الشامل ومنع نمو العفن، وهي تفاصيل أساسية حددناها من ملاحظات المستخدمين.

- مشابك قفل متساوية القفل: يسمح تصميم القفل رباعي الجوانب للغطاء بالضغط بشكل موحد على الحافة الزجاجية، مما يضمن إحكام الإغلاق في جميع النقاط.

| الميزة الأساسية | تركيزنا التقني | لماذا هو أكثر أهمية في عام 2025 |

|---|---|---|

| مادة الزجاج | يجب أن يكون من زجاج البورسليكات العالي | تتزايد مطالب المستهلكين بالسلامة والمتانة؛ وتتوافق المنتجات طويلة العمر مع الاتجاهات الصديقة للبيئة. |

| تصميم الختم | ختم سيليكون سميك وقابل للإزالة + أقفال من 4 جوانب | أصبح التركيز على نظافة الطعام وراحته في أعلى مستوياته على الإطلاق؛ فالتصميم سهل التنظيف يمنع بشكل فعال التعليقات السلبية. |

| تصميم سهل الاستخدام | حواف قابلة للتكديس ومضادة للحرق، وعلامات واضحة | في سوق تنافسي، تُعد تجربة المستخدم الممتازة هي المفتاح لتمييز المنتج وزيادة عمليات الشراء المتكررة. |

قبل تقديم طلب الشراء بالجملة، كيف يمكنك إجراء تقييم كامل لقوة المورد وموثوقيته؟

في عام 2025، ينطوي الطلب الكبير على مخاطر كبيرة. كمشتري، لديك الحق والحاجة إلى طرح الأسئلة: "هل يمكنك حقًا التعامل مع حجم طلبي؟ كيف تبدو عملية مراقبة الجودة لديكم في الواقع؟ نحن نرحب بهذه الأسئلة الصعبة من جميع المشترين "الأذكياء".

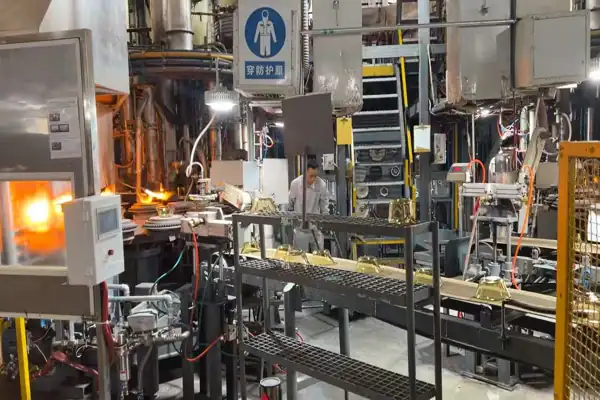

قبل تقديم طلب الشراء بالجملة، يجب عليك إجراء تقييم شامل ثلاثي الأبعاد: مراجعة أنظمة الإدارة الخاصة بهم من خلال وثائق مثل ISO 9001 وBSCI، وتقييم ظروف الإنتاج الفعلية من خلال جولة افتراضية عالية الوضوح (HD) أو جولة في المصنع 9{#ref-9}وفهم مرونة سلسلة التوريد الخاصة بهم وقدراتهم على الاستجابة للمخاطر من خلال التواصل المتعمق.

نحن لا نخشى أبدًا من بذل العميل للعناية الواجبة ونؤمن إيمانًا راسخًا بأن الشفافية هي السبيل الوحيد لبناء الثقة. ولهذا السبب نرحب دائمًا بالعملاء لإجراء جولات في الموقع أو جولات افتراضية عالية الوضوح لمصنعنا الذي تبلغ مساحته 200,000㎡ (حوالي 2.15 مليون قدم مربع). نحن نريدك أن ترى بنفسك خطوط إنتاجنا الآلية المنظمة، وعمليات فحص الجودة الصارمة، ومخزوننا الوافر من المواد الخام من البوراكس المستوردة من الولايات المتحدة وتركيا - وهذا هو مصدر ثقتنا في استقرار سلسلة التوريد لدينا. المورد القدير والواثق لا يخشى أبدًا من فتح أبوابه للعملاء.

القائمة المرجعية للتقييم الشامل لقوة الموردين لعام 2025

أنصحك باستخدام نموذج التقييم هذا لتقييم أي مورد محتمل.

1. "القوة الصلبة" لنظم الإدارة

هذا هو الأساس لتقييم احترافية المورد.

- إدارة الجودة (ISO 9001): هل لديهم عملية موحدة لضمان جودة ثابتة لكل دفعة؟

- المسؤولية الاجتماعية (BSCI/SMETA): هل شريكك مؤسسة مسؤولة؟ هذا يحمي علامتك التجارية من التورط في أخبار سلبية.

- الإدارة البيئية (ISO 14001): إذا كان المورد حاصلاً على هذه الشهادة، فهذا يشير إلى أنه رائد في مجال التنمية المستدامة وأكثر انسجاماً مع الفلسفة البيئية لعلامتك التجارية.

2. "الرؤية تصديق" في موقع الإنتاج

وسواء كانت الزيارة شخصية أو افتراضية، يجب التركيز على هذه النقاط:

- الترتيب والتنظيم (5S): المصنع المُدار جيدًا سيكون حتمًا نظيفًا ومنظمًا.

- حالة المعدات: يؤثر تقدم معداتهم وصيانتها بشكل مباشر على كفاءة الإنتاج ودقة المنتج.

- محطات فحص الجودة: هل هناك محطات مخصصة لمراقبة الجودة في النقاط الرئيسية لخط الإنتاج (المواد الواردة، ما بعد التشكيل، ما قبل التعبئة والتغليف)؟

3. "مقاومة المخاطر" في سلسلة التوريد

هذا هو الجزء الأكثر أهمية في تقييم المورد في البيئة الحالية.

- توريد المواد الخام: هل لديهم العديد من موردي المواد الخام لتنويع المخاطر؟

- استراتيجية المخزون: هل يحتفظون بمخزون آمن من المواد الخام الرئيسية والمنتجات القياسية؟

- آلية التواصل: إذا واجهوا تأخيرات في الإنتاج أو مشاكل في الشحن، هل لديهم نظام تواصل وتحذير واضح واستباقي؟

أخيرًا، أنصح العملاء دائمًا باستخدام أمر تجريبي صغير 10{#ref-10} لاختبار جميع الجوانب المذكورة أعلاه. لا يتعلق الأمر باختبار المنتج فقط؛ بل باختبار سرعة استجابتنا واحترافيتنا وقدرتنا على حل المشاكل خلال عملية التعاون بأكملها.

الخاتمة

بصفتك الشركة المصنعة للأواني الزجاجية ملتزمين ببناء شراكات طويلة الأجل، فإن نصيحتي الأخيرة هي التالية: يرجى النظر إلى ما وراء السعر. في السوق المضطربة لعام 2025، سيكون أفضل شريك لك هو المؤسسة التي تستثمر باستمرار في الجودة، وتتبنى بنشاط التنمية المستدامة، وتبني سلسلة توريد مرنة. لقد بنينا في PYGLASS أعمالنا على هذه المبادئ لأننا نؤمن إيمانًا راسخًا بأن هذه هي الطريقة الوحيدة لتجاوز الدورات وكسب السوق مع عملائنا.

تحدث مباشرة مع المؤسس: تحديد الجيل القادم من معايير المنتجات

في سوق عام 2025، خياراتك أهم من جهودك. لن تسفر سلسلة التوريد المتواضعة إلا عن نتائج متواضعة. ولكي تكون رائداً في السوق، يجب أن تتوافق مع المصنعين الذين يفكرون كقادة.

أشرف شخصياً على توجيه الشراكة الاستراتيجية في PYGLASS. ولهذا السبب، فإنني أتيح واتسابي الشخصي لإجراء محادثات متعمقة مع صانعي القرار الحقيقيين للعلامة التجارية ذوي الرؤية.

هذا ليس من أجل عروض الأسعار الروتينية. هذا للحوار حول مستقبل علامتك التجارية وابتكار المنتجات واستراتيجية السوق. إذا كنت مستعدًا للقيادة، فأنا مستعد للتحدث.

المسح الضوئي لإضافة واتساب المؤسس الشخصي

الحواشي

1. تعرف على اختبار المواد الملامسة للأغذية من Intertek، وهي هيئة عالمية رائدة في مجال إصدار الشهادات. ↩︎

2. رؤى الخبراء من شركة ماكنزي حول بناء مرونة سلسلة التوريد وجاهزيتها في السوق اليوم. ↩︎

3. معلومات رسمية عن مبادرة أمفوري للامتثال والمسؤولية الاجتماعية (Amfori BSCI)، وهي مبادرة رائدة في مجال الامتثال والمسؤولية الاجتماعية. ↩︎

4. لمحة عامة عن معايير إدارة الجودة ISO 9001 الصادرة عن المنظمة الدولية لتوحيد المقاييس. ↩︎

5. استكشف حلول B2B O2B OEM/ODM للأواني الزجاجية المخصصة لرفع مستوى خط إنتاج علامتك التجارية. ↩︎

6. تعرف على مهمة مجلس الإشراف على الغابات (FSC) لتعزيز الحراجة المسؤولة. ↩︎

7. اكتشف مجموعة من منتجات زجاج البورسليكات العالي المصممة لقوة التحمل والسلامة. ↩︎

8. شرح لخصائص زجاج البورسليكات من شركة SCHOTT، وهي شركة عالمية رائدة في مجال التصنيع. ↩︎

9. قم بجولة افتراضية في مصنع حديث للأواني الزجاجية لمشاهدة الإنتاج ومراقبة الجودة بشكل مباشر. ↩︎

10. اتصل بأحد الموردين للاستفسار عن تقديم طلب تجريبي لاختبار جودة المنتج والخدمة. ↩︎