ينظر الكثير من الناس إلى السعر فقط عند شراء الأواني الزجاجية، متجاهلين مخاطر السلامة التي تأتي مع اختلاف المواد. يمكن أن يؤدي اختيار المادة الخاطئة، في أفضل الأحوال، إلى تغيير مذاق طعامك، وفي أسوأ الأحوال، قد يؤدي إلى التحطم والإصابة. بصفتي ممارسًا في صناعة الزجاج، فقد رأيت الكثير من شكاوى العملاء ومرتجعاتهم من اختيارهم الخاطئ زجاج الصودا والليمون 1{#ref-1}.

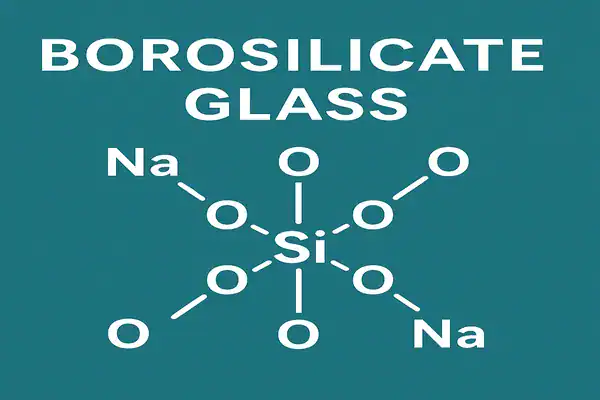

زجاج البورسليكات أكثر مقاومة للحرارة وأكثر أمانًا وملائم للاستخدام في المطبخ من زجاج الجير الصودا، خاصةً في التطبيقات التي تتضمن التسخين والتبريد والغسيل المتكرر. تكمن ميزته الأساسية في مكون كيميائي فريد من نوعه - ثلاثي أكسيد البورون - الذي يوفر معامل تمدد حراري منخفض للغاية وثبات كيميائي متميز.

على الرغم من أنهما قد يبدوان متشابهين، إلا أن هذين النوعين من الزجاج لهما اختلافات جوهرية في تركيبتهما وأدائهما. ستوفر هذه المقالة الدليل الأكثر مباشرة وعملية لفهم هذه الاختلافات، مما يتيح لك اتخاذ قرارات أكثر ذكاءً، سواء كنت تبحث عن مصادر لشركتك أو تختار لمطبخك الخاص.

ما هي الاختلافات الحقيقية بين زجاج الصودا والجير وزجاج البورسليكات؟

قد لا تعرف ذلك، ولكن حوالي 90% من الأواني الزجاجية اليومية مصنوعة من زجاج الجير الصودا. والمشكلة هي أنه عند تعريضه لدرجات حرارة عالية، يمكن أن يتحطم مع "الكسر".

يشتمل زجاج البورسليكات على البورون في تركيبته الكيميائية، مما يسمح له بتحمل التغيرات الشديدة في درجات الحرارة ومقاومة التآكل الكيميائي، مما يجعله الخيار الأفضل للمختبرات والمطابخ الاحترافية. لا يتمتع زجاج الجير الصودا بهذه الخصائص.

لمحة سريعة عن الاختلافات الأساسية

| الميزة | زجاج الصودا والليمون | زجاج البورسليكات |

|---|---|---|

| المكونات الرئيسية | ثاني أكسيد السيليكون + أكسيد الصوديوم + أكسيد الكالسيوم | ثاني أكسيد السيليكون + ثالث أكسيد ثلاثي البورون |

| صعوبة التصنيع | نقطة انصهار بسيطة ومنخفضة | متطلبات درجة حرارة أعلى، عملية أكثر تعقيدًا |

| التكلفة | منخفضة | عالية |

تحليل متعمق: كيف يؤثر التكوين على الأداء

1. المواد الخام ودرجة حرارة الانصهار

يبدأ الاختلاف الأساسي من المواد الخام. إن زجاج الصودا والجير غير مكلف لأن أكسيد الصوديوم (الصودا) وأكسيد الكالسيوم (الجير) يعملان كعاملين متدفقين، مما يقلل من درجة انصهار السيليكا. وهذا يوفر الطاقة ووقت الإنتاج، ولكنه يأتي على حساب بنية جزيئية أقل استقرارًا.

ومع ذلك، يستبدل زجاج البورسليكات بعض عوامل التدفق هذه بمكون رئيسي: ثالث أكسيد البورون (B₂O₃) 2{#ref-2}. ويعني هذا التغيير أنه يتطلب درجة حرارة انصهار أعلى بكثير (حوالي 1600 درجة مئوية)، مما يتطلب أفرانًا أكثر تقدمًا واستهلاكًا أعلى للطاقة. وهذا الارتفاع في تكلفة الإنتاج مسؤول بشكل مباشر عن أدائه المتفوق والأكثر استقرارًا وهو السبب الرئيسي لفرق السعر.

2. التركيب الكيميائي والاستقرار الكيميائي

تعمل إضافة ثالث أكسيد البورون على تحسين الشبكة الزجاجية على المستوى الذري، مما يخلق روابط أقوى بين الجزيئات. وينتج عن ذلك ميزتان أساسيتان: أولاً، يقلل بشكل كبير من معامل التمدد الحراري 3{#ref-3}مما يمنع تراكم الضغط العالي أثناء التغيرات في درجات الحرارة. ثانيًا، تعزز هذه الميزة الخمول الكيميائي، مما يجعل الزجاج شديد المقاومة للتفاعل مع الأحماض والقواعد.

لماذا يعتبر زجاج البورسليكات الخيار الأول لأدوات المطبخ؟

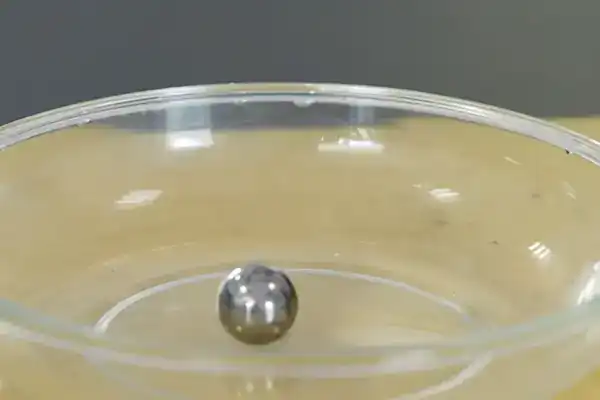

لقد اختبر العديد من الأشخاص تلك اللحظة المحبطة عندما تتشقق حاوية زجاج الصودا والجير في الميكروويف. وهذا نتيجة مباشرة للاختلاف الكبير بين المادتين. مقاومة الصدمات الحرارية 4{#ref-4}.

يمكن لزجاج البورسليكات أن يتحمل تغيرات كبيرة في درجات الحرارة تصل إلى 150 درجة مئوية (300 درجة فهرنهايت) أو أكثر، مما يسمح له بالتنقل بأمان بين الثلاجة والميكروويف والفرن. إلا أن زجاج الصودا والجير لا يتحمل سوى صدمة حرارية تتراوح بين 40-60 درجة مئوية (104-140 درجة فهرنهايت).

مقارنة أداء الصدمات الحرارية

| الميزة | زجاج الصودا والليمون | زجاج البورسليكات |

|---|---|---|

| مقاومة الصدمات الحرارية | ~40 درجة مئوية-60 درجة مئوية | ~150 درجة مئوية إلى 300 درجة مئوية |

| معامل التمدد الحراري | عالية | منخفضة للغاية |

| استخدام الميكروويف/الفرن | ❌ محفوف بالمخاطر للغاية | ✅ آمن للاستخدام المنتظم |

| تدفئة مباشرة من الثلاجة | ❌ محظور تمامًا | ✅ آمن |

تحليل متعمق: الدور الحاسم لمعامل التمدد الحراري

"الصدمة الحرارية" هي أمر ثابت في المطبخ: نقل وعاء من الثلاجة الباردة إلى الميكروويف الساخن أو سكب الماء المغلي في كوب. يعتمد نجاة الزجاج من الصدمة على معامل التمدد الحراري.

- زجاج البورسليكات: يتميز بمعامل تمدد حراري منخفض للغاية (حوالي 3.3 × 10-⁶/ك). عندما تتغير درجة الحرارة بشكل مفاجئ، بالكاد يتغير حجمه، مما يمنع تراكم الإجهاد الحرج بين الجدران الداخلية والخارجية. ولهذا السبب لا يتصدع.

- زجاج الصودا والليمون: له معامل أعلى بكثير (حوالي 9.0 x 10-⁶/ك)، أي ما يقرب من ثلاثة أضعاف معامل البورسليكات. تتسبب التغيرات السريعة في درجة الحرارة في تمدد أو تقلص جدرانه الداخلية والخارجية بمعدلات مختلفة، مما يؤدي إلى إجهاد داخلي هائل يؤدي إلى التحطم.

هذا الاختلاف مهم للغاية بالنسبة لأدوات المطبخ مثل أطباق الخبز 5{#ref-5}, حاويات تخزين الطعام 6{#ref-6}وأكواب القياس والجرار التي تخضع للتسخين والتبريد. تحتاج إلى وعاء لا تتحطم ولا تتسرب إليها الشوائب لحماية طعامك وعائلتك

هل زجاج الجير الصودا أكثر هشاشة؟ مقارنة بين القوة

للوهلة الأولى، غالبًا ما تبدو الأواني الزجاجية المصنوعة من البورسليكات أخف وزنًا وأرق من نظيرتها المصنوعة من الجير الصودا. ومع ذلك، فإن هذا في الواقع دليل على قوته الفائقة.

يتميز زجاج البورسليكات في شكله القياسي بمقاومة أعلى للصدمات والخدوش من زجاج الصودا والجير العادي. وعلى الرغم من أن التقسية يمكن أن تحسن من قوة زجاج الصودا والجير، إلا أن متانته الإجمالية لا تزال غير متكافئة.

مقارنة الخواص الميكانيكية

| الميزة | زجاج الصودا والليمون (قياسي) | زجاج الصودا والليمون (مقسّى) | زجاج البورسليكات |

|---|---|---|---|

| مقاومة السقوط | فقير | متوسط-جيد | جيد |

| صلابة السطح/مقاومة الخدوش | متوسط | متوسط-عالي | عالية |

| نمط الكسر | شظايا كبيرة وحادة | يتفتت إلى قطع صغيرة لا حصر لها | قطع أكبر حجماً ذات حواف باهتة |

| المتانة على المدى الطويل | عادل | متوسط | طويلة الأمد |

تحليل متعمق: نظرة شاملة على القوة والمتانة

1. صلابة السطح: يتميز زجاج البورسليكات بسطح أكثر صلابة، مما يجعله مقاومًا للخدوش الناتجة عن الاستخدام اليومي والتنظيف. فالخدوش ليست مجرد عيوب تجميلية؛ بل هي نقاط إجهاد وأرض خصبة للبكتيريا التي تؤثر على قوة الزجاج وسلامته بشكل عام.

2. حدود الزجاج المقسّى: في حين أن زجاج الصودا والليمون المقسّى 7{#ref-7} يتمتع بمقاومة جيدة للصدمات، إلا أن خطر "الانفجار التلقائي" وميله إلى التفكك الكامل عند الكسر يمكن أن يشكل خطرًا على السلامة في بعض سيناريوهات المطبخ. وعلى النقيض من ذلك، فإن قوة زجاج البورسليكات متأصلة في تركيبته المادية المستقرة، وليست ناجمة عن الإجهاد المادي، مما يجعله أكثر موثوقية.

بالنسبة لأي تطبيق يتضمن الاستخدام المتكرر والتسخين المتكرر والغسيل المنتظم، فإن زجاج البورسليكات هو الخيار الأكثر موثوقية بشكل لا لبس فيه.

هل زجاج البورسليكات أكثر أمانًا حقًا؟ ماذا عن الرصاص أو السموم؟

لقد طُرح عليّ هذا السؤال مرات لا حصر لها من قبل العملاء في أمريكا الشمالية وأوروبا. بالنسبة لأي مشترٍ محترف، فإن السلامة والامتثال أمران غير قابلين للتفاوض.

يتوافق زجاج البورسليكات الحقيقي عالي الجودة مع المعايير الدولية لملامسة الأغذية مثل FDA و LFGB و DGCCRF. لا يحتوي على الرصاص أو الكادميوم أو المعادن الثقيلة الضارة الأخرى وهو خامل كيميائياً، مما يعني أنه لن يرشح أي مواد في طعامك.

مقارنة معايير سلامة الأغذية

| قياسي | زجاج الصودا والليمون (قياسي) | زجاج البورسليكات |

|---|---|---|

| امتثال إدارة الغذاء والدواء الأمريكية (الولايات المتحدة الأمريكية) 8{#ref-8} | يمكن أن يجتاز البعض | ✅ قياسي |

| LFGB (ألمانيا) 9{#ref-9} | معدل نجاح منخفض | ✅ قياسي |

| المحتوى الرئيسي | قد تحتوي على آثار (يعتمد على نقاء المادة الخام) | خالي من الرصاص |

| ملامسة الأغذية الحمضية/القلوية | خطر التآكل والرشح | مقاومة عالية للتآكل |

التحليل المتعمق: أهمية الاستقرار الكيميائي

لقد قمت شخصيًا بقيادة فريقي لإخضاع خط إنتاجنا من البورسليكات لاختبار معايير الاتحاد الأوروبي، والذي يتضمن اختبارات ترشيح مطولة في بيئة حمض الأسيتيك. وكانت النتيجة "صفر في الكشف".

- مقاومة الأحماض والقلويات: سواء كنت تخزن عصير الليمون أو الخل أو تستخدم غسالة الصحون، فإن زجاج البورسليكات يحافظ على سلامة سطحه. فهو لن يتآكل أو يتغيّم بمرور الوقت مثل زجاج الجير الصودا.

- سطح غير مسامي: سطح زجاج البورسليكات أملس وغير مسامي. فهو لا يمتص روائح الطعام أو البقع، ويسهل تنظيفه ولا يؤوي البكتيريا.

هذا هو السبب في إصرار العلامات التجارية من الدرجة الأولى لرضّاعات الأطفال وحاويات تخزين حليب الأم وأدوات المختبرات الطبية على استخدام زجاج البورسليكات - عندما يتعلق الأمر بالسلامة، لا يمكن أن يكون هناك أي تنازلات.

هل فرق التكلفة يستحق كل هذا العناء؟ كيف يمكنني الاختيار؟

هذا هو السؤال الرئيسي بالنسبة للعديد من عملاء B2B: زجاج البورسليكات يكلف عدة مرات أكثر، فهل يستحق الأمر ذلك؟

إذا كان سوقك المستهدف يقدّر السلامة والمتانة والمنتجات الصديقة للبيئة القابلة لإعادة الاستخدام، فإن القيمة طويلة الأجل وسمعة العلامة التجارية المكتسبة من الاستثمار في زجاج البورسليكات تستحق بالتأكيد قيمة العلاوة.

مشورة التوريد المستندة إلى السيناريو

| التطبيق | نوع الزجاج الموصى به | السبب |

|---|---|---|

| حاويات الطعام القابلة للتسخين في الميكروويف | زجاج البورسليكات ✅ | الاستقرار الحراري أمر بالغ الأهمية للسلامة؛ لا يوجد خطر انفجار. |

| أطباق الخبز | زجاج البورسليكات ✅ | يجب أن يتحمل الاختلافات الشديدة في درجات الحرارة بين الفرن والثلاجة. |

| رضّاعات الأطفال/علب الطعام | زجاج البورسليكات ✅ | غير سام على الإطلاق، ويتحمل التعقيم بدرجة حرارة عالية. |

| برطمانات تخزين محكمة الإغلاق | زجاج البورسليكات ✅ | خامل كيميائياً؛ لن يتفاعل مع أي نوع من الأطعمة. |

| أكواب الشرب اليومية | زجاج الصودا والليمون ✅ | فعالة من حيث التكلفة للاستخدامات التي لا تنطوي على تغيرات شديدة في درجات الحرارة. |

| عبوات الطعام ذات الاستخدام الواحد 10{#ref-10} | زجاج الصودا والليمون ✅ | قيمة عالية مقابل المال، تلبي الاحتياجات الأساسية. |

| أواني زجاجية مزخرفة | زجاج الصودا والليمون ✅ | الأداء العالي غير مطلوب. |

توصيتي الأخيرة هي لا تحتاج إلى استخدام البورسليكات في كل شيء. ولكن بالنسبة لأي تطبيق يتضمن العناصر الرئيسية الثلاثة لـ "التسخين + ملامسة الطعام + الاستخدام المتكرر،" يجب عليك عدم خفض التكاليف

الخاتمة

في حين قد يبدو زجاج الصودا والجير وزجاج البورسليكات متشابهين، إلا أنهما مختلفان تمامًا من حيث المقاومة الحرارية والاستقرار الكيميائي والقوة والسلامة. على الرغم من أن زجاج البورسليكات له تكلفة أولية أعلى، إلا أن القيمة التي يقدمها من حيث العمر الافتراضي الطويل، والسلامة الفائقة، والصورة الإيجابية للعلامة التجارية لا تُقاس. بالنسبة لبائعي التجزئة والعلامات التجارية التي تركز على الجودة والسلامة والاستدامة، فهو الاستثمار الأكثر جدارة بالثقة والأصح على المدى الطويل.

وجهة نظر علامتي التجارية

نبذة عن PYGLASS

اسم العلامة التجارية: باي جلاس

الشعار: أكثر أماناً - أكثر صحة - أكثر اخضراراً

الموقع الإلكتروني: www.slyprc.com

مهمتنا هي تعزيز السلامة والصحة والمحافظة على البيئة في كل وجبة وكل لحظة تخزين من خلال أواني البورسليكات الزجاجية الفاخرة.

نحن نصنع زجاج البورسليكات الحقيقي فقط. نحن نقدم خدماتنا لأكثر من 50 علامة تجارية وتجار تجزئة معروفين من أمريكا الشمالية وأوروبا وأمريكا اللاتينية، وجميع منتجاتنا معتمدة لتلبية المعايير الصارمة الخاصة بالمواد الغذائية، بما في ذلك إدارة الأغذية والعقاقير (FDA) و LFGB و DGCCRF.

إذا كنت تبحث عن مورد للأواني الزجاجية الآمنة حقًا وذات الجودة العالية، فسنكون شريكك الموثوق به على المدى الطويل.

الحواشي

1. تعرف على التركيب والاستخدامات الشائعة لأكثر أنواع الزجاج انتشاراً. ↩︎

2. اكتشف الخواص الكيميائية للمكون الرئيسي الذي يمنح زجاج البورسليكات ثباته. ↩︎

3. دليل هندسي لفهم كيفية تمدد المواد وتقلصها مع تغيرات درجة الحرارة. ↩︎

4. شرح تقني لسبب تشقق بعض المواد تحت التغيرات السريعة في درجات الحرارة. ↩︎

5. استكشف أطباق الخبز المصنوعة من البورسليكات عالية الأداء والمصممة لضمان السلامة من الفرن إلى المائدة. ↩︎

6. عرض مجموعة من أوعية الطعام المصنوعة من البورسليكات التي تضمن السلامة والنضارة. ↩︎

7. لمحة عامة من مجلة Scientific American عن كيفية صنع الزجاج المقسّى وسبب تحطم الزجاج بشكل مختلف. ↩︎

8. المعلومات الرسمية لإدارة الغذاء والدواء الأمريكية عن المواد المعتمدة للتلامس مع الأغذية. ↩︎

9. تفاصيل عن المدونة الألمانية للأغذية والأعلاف (LFGB) لاختبار سلامة المنتجات. ↩︎

10. معلومات للشركات التي تبحث عن موردين موثوقين للأواني الزجاجية لمختلف التطبيقات. ↩︎