Mnoho lidí se při nákupu skleněného nádobí dívá pouze na cenu a ignoruje bezpečnostní rizika, která s sebou nesou rozdíly v materiálu. Výběr špatného materiálu může v lepším případě změnit chuť jídla, v horším případě vést k rozbití a zranění. Jako praktik ve sklářském průmyslu jsem se setkal s příliš mnoha stížnostmi a vrácenými výrobky od zákazníků, kteří si chybně vybrali sklo. sodovkovo-vápenná sklenice 1{#ref-1}.

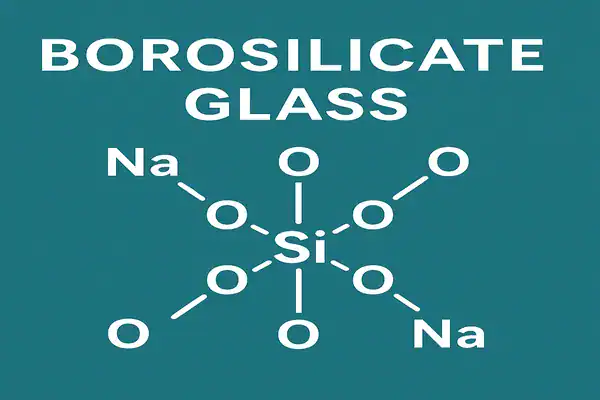

Borosilikátové sklo je žáruvzdornější, bezpečnější a vhodnější pro použití v kuchyni než sodnovápenaté sklo, zejména pro použití při ohřevu, chlazení a častém mytí. Jeho hlavní výhoda spočívá v jedinečné chemické složce - oxidu boritém - která zajišťuje extrémně nízký koeficient tepelné roztažnosti a vynikající chemickou stabilitu.

Ačkoli mohou vypadat podobně, tyto dva typy skel se zásadně liší svým složením a vlastnostmi. Tento článek vám poskytne co nejpřímější a nejpraktičtější návod, jak těmto rozdílům porozumět, a umožní vám tak činit chytřejší rozhodnutí, ať už sháníte sklo pro svou firmu, nebo vybíráte pro svou vlastní kuchyň.

Jaké jsou skutečné rozdíly mezi sodnovápenatým a borosilikátovým sklem?

Možná to nevíte, ale přibližně 90% každodenního skleněného nádobí je vyrobeno ze sodnovápenatého skla. Problém je, že když ho vystavíte vysokým teplotám, může se roztříštit "prasknutím".

Borosilikátové sklo obsahuje ve své chemické struktuře bór, díky čemuž odolává extrémním teplotním změnám a chemické korozi, což z něj činí nejlepší volbu pro laboratoře a profesionální kuchyně. Sodnovápenaté sklo tyto vlastnosti nemá.

Přehled základních rozdílů

| Funkce | Sklenice na sodovku a vápno | Borosilikátové sklo |

|---|---|---|

| Klíčové součásti | Oxid křemičitý + oxid sodný + oxid vápenatý | Oxid křemičitý + Trioxid boru |

| Obtížnost výroby | Jednoduchý, nízký bod tání | Vyšší teplotní nároky, složitější proces |

| Náklady | Nízká | Vysoká |

Hloubková analýza: Jak složení ovlivňuje výkonnost

1. Suroviny a teplota tání

Zásadní rozdíl začíná u surovin. Sodnovápenaté sklo je levné, protože oxid sodný (soda) a oxid vápenatý (vápno) působí jako tavidla a snižují bod tání oxidu křemičitého. To šetří energii a výrobní čas, ale za cenu méně stabilní molekulární struktury.

Borokřemičité sklo však nahrazuje některé z těchto tavidel klíčovou složkou: oxid boritý (B₂O₃) 2{#ref-2}. Tato změna znamená, že vyžaduje mnohem vyšší teplotu tavení (přibližně 1600 °C), což vyžaduje modernější pece a vyšší spotřebu energie. Tyto vyšší výrobní náklady jsou přímo zodpovědné za jeho lepší a stabilnější výkon a jsou hlavním důvodem cenového rozdílu.

2. Chemická struktura a stabilita

Přídavek oxidu boritého optimalizuje síť skla na atomární úrovni a vytváří pevnější vazby mezi molekulami. To přináší dvě základní výhody: za prvé, výrazně snižuje hladinu koeficient tepelné roztažnosti 3{#ref-3}, což zabraňuje vzniku vysokého napětí při změnách teplot. Za druhé zvyšuje chemickou inertnost, takže sklo je vysoce odolné vůči reakcím s kyselinami a zásadami.

Proč je borosilikátové sklo první volbou pro kuchyňské nádobí?

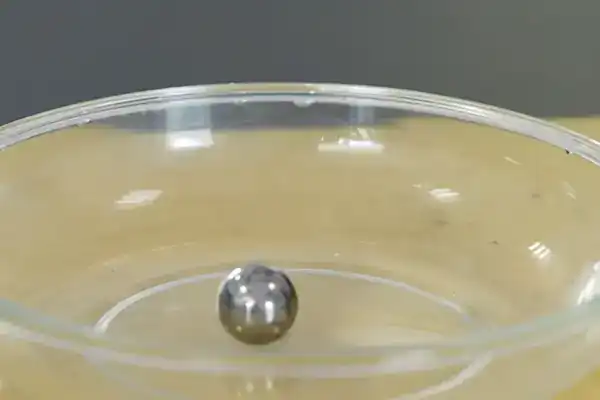

Mnoho lidí zažilo ten frustrující okamžik, kdy jim v mikrovlnné troubě praskla skleněná nádoba na sodovku. Je to přímý důsledek značně rozdílných vlastností obou materiálů. odolnost proti tepelným šokům 4{#ref-4}.

Borosilikátové sklo odolává prudkým změnám teploty o 150 °C a více, takže může bezpečně přecházet mezi chladničkou, mikrovlnnou troubou a troubou. Sodnovápenaté sklo však zvládne pouze teplotní šok o teplotě přibližně 40-60 °C (104-140 °F).

Srovnání výkonu při teplotním šoku

| Funkce | Sklenice na sodovku a vápno | Borosilikátové sklo |

|---|---|---|

| Odolnost proti teplotním šokům | ~40°C-60°C | ~150°C-300°C |

| Koeficient tepelné roztažnosti | Vysoká | Extrémně nízká |

| Používání mikrovlnné trouby/trouby | ❌ Extrémně rizikové | ✅ Bezpečné pro pravidelné používání |

| Ohřev přímo z chladničky | ❌ Přísně zakázáno | ✅ Bezpečné |

Hloubková analýza: Rozhodující role koeficientu tepelné roztažnosti

"Tepelný šok" je v kuchyni stálým jevem: přenášení nádoby ze studené lednice do horké mikrovlnné trouby nebo nalévání vroucí vody do sklenice. Zda sklenice přežije, závisí na její koeficient tepelné roztažnosti.

- Borosilikátové sklo: Má extrémně nízký koeficient tepelné roztažnosti (přibližně 3,3 x 10-⁶/K). Při náhlé změně teploty se jeho objem téměř nemění, což zabraňuje vzniku kritického napětí mezi vnitřní a vnější stěnou. Proto nepraská.

- Sklenice na sodovku a vápno: Má mnohem vyšší koeficient (přibližně 9,0 x 10-⁶/K), téměř třikrát vyšší než borosilikát. Rychlé změny teploty způsobují, že se jeho vnitřní a vnější stěny rozpínají nebo smršťují různou rychlostí, což vytváří obrovské vnitřní napětí, které vede k roztříštění.

Tento rozdíl je rozhodující pro kuchyňské předměty, jako jsou nádoby na pečení 5{#ref-5}, nádoby na skladování potravin 6{#ref-6}, odměrky a sklenice, které se zahřívají a chladí. Potřebujete nádobu, která se netříští a nevyluhuje nečistoty. chránit své potraviny a svou rodinu.

Je sodovkové sklo křehčí? Srovnání pevnosti

Na první pohled je borosilikátové sklo často lehčí a tenčí než jeho sodnovápenaté protějšky. Ve skutečnosti to však svědčí o jeho vyšší pevnosti.

Ve své standardní podobě má borosilikátové sklo vyšší odolnost proti nárazu a poškrábání než běžné sodnovápenaté sklo. Kalení sice může zvýšit pevnost sodnovápenatého skla, ale jeho celková odolnost se mu stále nevyrovná.

Srovnání mechanických vlastností

| Funkce | Sklenice na sodovku (standardní) | Sodovkové sklo (tvrzené) | Borosilikátové sklo |

|---|---|---|---|

| Odolnost proti pádu | Špatný | Středně dobré | Dobrý |

| Tvrdost povrchu/odolnost proti poškrábání | Střední | Středně vysoké | Vysoká |

| Vzor rozbití | Velké ostré střepy | Roztříští se na nespočet malých kousků | Větší kusy s matnějšími hranami |

| Dlouhodobá odolnost | Spravedlivé | Střední | Dlouhodobá životnost |

Hloubková analýza: Komplexní pohled na pevnost a odolnost

1. Tvrdost povrchu: Borosilikátové sklo má tvrdší povrch, takže je odolné proti poškrábání při každodenním používání a čištění. Škrábance nejsou jen kosmetickou vadou; jsou to místa namáhání a živná půda pro bakterie, které ohrožují celkovou pevnost a bezpečnost skla.

2. Omezení tvrzeného skla: Zatímco kalené sodno-vápenaté sklo 7{#ref-7} má dobrou odolnost proti nárazu, jeho riziko "samovolného výbuchu" a tendence k úplnému rozpadu při rozbití může být v některých situacích v kuchyni bezpečnostním rizikem. Naproti tomu pevnost borosilikátového skla je dána jeho stabilním materiálovým složením, které není vyvoláno fyzikálním namáháním, takže je spolehlivější.

Pro jakékoli použití, které vyžaduje opakované používání, časté zahřívání a pravidelné mytí, je borosilikátové sklo jednoznačně spolehlivější volbou.

Je borosilikátové sklo skutečně bezpečnější? A co olovo nebo toxiny?

Tuto otázku mi klienti v Severní Americe a Evropě položili nesčetněkrát. Pro každého profesionálního kupujícího jsou bezpečnost a dodržování předpisů neoddiskutovatelné.

Skutečně kvalitní borosilikátové sklo splňuje mezinárodní normy pro styk s potravinami, jako jsou FDA, LFGB a DGCCRF. Neobsahuje olovo, kadmium ani jiné škodlivé těžké kovy a je chemicky inertní, což znamená, že se z něj do potravin nevyluhují žádné látky.

Srovnání norem pro bezpečnost potravin

| Standardní | Sklenice na sodovku (standardní) | Borosilikátové sklo |

|---|---|---|

| Dodržování předpisů FDA (USA) 8{#ref-8} | Někteří mohou projít | ✅ Standardní |

| LFGB (Německo) 9{#ref-9} | Nízká míra úspěšnosti | ✅ Standardní |

| Hlavní obsah | Může obsahovat stopy (závisí na čistotě suroviny) | Bezolovnaté |

| Kontakt s kyselými/alkalickými potravinami | Riziko koroze a vyluhování | Vysoká odolnost proti korozi |

Hloubková analýza: Význam chemické stability

Osobně jsem vedl svůj tým, který předložil naši řadu borosilikátových výrobků k testování podle norem EU, které zahrnuje dlouhodobé vyluhovací testy v prostředí kyseliny octové. Výsledkem byla "nulová detekce".

- Odolnost vůči kyselinám a alkáliím: Ať už skladujete citronovou šťávu, ocet nebo používáte myčku nádobí, borosilikátové sklo si zachovává celistvost povrchu. Časem nekoroduje ani se nezakalí, jako je tomu u sodnovápenatého skla.

- Neporézní povrch: Povrch borosilikátového skla je hladký a neporézní. Nepohlcuje pachy ani skvrny od jídla, snadněji se čistí a nedochází na něm k množení bakterií.

Proto špičkové značky kojeneckých lahví, nádob na uchovávání mateřského mléka a lékařského laboratorního nádobí trvají na používání borosilikátového skla - pokud jde o bezpečnost, nelze dělat kompromisy.

Stojí rozdíl v nákladech za to? Jak si mám vybrat?

To je klíčová otázka pro mnoho B2B klientů: borosilikátové sklo stojí několikanásobně více, vyplatí se to?

Pokud váš cílový trh oceňuje bezpečnost, trvanlivost a opakovaně použitelné, ekologické výrobky, pak dlouhodobá hodnota a pověst značky získaná investicí do borosilikátového skla rozhodně stojí za příplatek.

Poradenství v oblasti získávání zdrojů na základě scénářů

| Aplikace | Doporučený typ skla | Důvod |

|---|---|---|

| Mikrovlnné nádoby na potraviny | Borosilikátové sklo ✅ | Tepelná stabilita je rozhodující pro bezpečnost; nehrozí nebezpečí výbuchu. |

| Nádobí na pečení | Borosilikátové sklo ✅ | Musí odolávat extrémním teplotním rozdílům mezi troubou a chladničkou. |

| Dětské láhve / sklenice na potraviny | Borosilikátové sklo ✅ | Absolutně netoxický, odolává sterilizaci při vysoké teplotě. |

| Vzduchotěsné skladovací nádoby | Borosilikátové sklo ✅ | Chemicky inertní; nereaguje s žádným typem potravin. |

| Sklenice na pití pro každý den | Sklenice na sodovku ✅ | Cenově výhodné pro použití bez extrémních teplotních změn. |

| Jednorázové nádoby na potraviny 10{#ref-10} | Sklenice na sodovku ✅ | Vysoká hodnota za peníze, splňuje základní potřeby. |

| Dekorativní sklo | Sklenice na sodovku ✅ | Vysoký výkon není vyžadován. |

Moje poslední doporučení je následující: Nemusíte používat borosilikát na všechno. Ale pro jakoukoli aplikaci, která zahrnuje tři klíčové prvky "Zahřívání + kontakt s potravinami + opakované použití," nikdy byste neměli snižovat náklady.

Závěr

Ačkoli se sodnovápenaté a borosilikátové sklo mohou zdát podobné, jejich tepelná odolnost, chemická stabilita, pevnost a bezpečnost jsou na hony vzdálené. Přestože je počáteční cena borokřemičitého skla vyšší, jeho hodnota v podobě prodloužené životnosti, vyšší bezpečnosti a pozitivního image značky je nevyčíslitelná. Pro prodejce a značky zaměřené na kvalitu, bezpečnost a udržitelnost je to důvěryhodnější a správnější dlouhodobá investice.

Úhel pohledu mé značky

O společnosti PYGLASS

Název značky: PYGLASS

Slogan: Bezpečnější - zdravější - ekologičtější

Webové stránky: www.slyprc.com

Naším posláním je zvýšit bezpečnost, zdraví a ekologickou šetrnost každého jídla a každého okamžiku skladování prostřednictvím prvotřídního borosilikátového skla.

Vyrábíme pouze pravé borosilikátové sklo. Obsluhujeme více než 50 známých značek a prodejců ze Severní Ameriky, Evropy a Latinské Ameriky a všechny naše výrobky jsou certifikovány tak, aby splňovaly přísné potravinářské normy, včetně FDA, LFGB a DGCCRF.

Pokud hledáte dodavatele skutečně bezpečného a vysoce kvalitního skla, budeme vaším spolehlivým a dlouhodobým partnerem.

Poznámky pod čarou

1. Seznamte se se složením a běžným použitím nejrozšířenějšího typu skla. ↩︎

2. Objevte chemické vlastnosti klíčové složky, která dodává borosilikátovému sklu stabilitu. ↩︎

3. Inženýrský průvodce pro pochopení toho, jak se materiály rozpínají a smršťují při změnách teploty. ↩︎

4. Technické vysvětlení, proč některé materiály praskají při rychlých změnách teploty. ↩︎

5. Prozkoumejte vysoce výkonné borosilikátové nádoby na pečení, které jsou navrženy tak, aby byly bezpečné od trouby až po stůl. ↩︎

6. Prohlédněte si kolekci borosilikátových nádob na potraviny, které zajišťují bezpečnost a čerstvost. ↩︎

7. Přehled z časopisu Scientific American o tom, jak se vyrábí tvrzené sklo a proč se různě tříští. ↩︎

8. Oficiální informace Úřadu pro potraviny a léčiva USA o materiálech schválených pro styk s potravinami. ↩︎

9. Podrobnosti o německém zákoníku pro potraviny a krmiva (LFGB) pro testování bezpečnosti výrobků. ↩︎

10. Informace pro podniky, které hledají spolehlivé dodavatele skleněného nádobí pro různé aplikace. ↩︎