Are you tired of food spoiling just a few days after you buy it? Air is the main enemy of freshness. It causes good food to go bad, leading to waste and unhappy customers. Vacuum seal glass containers claim to solve this by removing the air. But do they really deliver on this promise?

Yes, vacuum seal glass containers work very well. By removing most of the air with a pump, they stop the growth of bacteria and mold. This keeps food fresh three to five times longer than standard containers, saving money and reducing food waste.

I have been in the glass manufacturing industry for over 15 years. In that time, I have seen many kitchen trends come and go. The move toward vacuum sealing is a big one. It is not just a sales gimmick; it is based on real, simple science. But how these containers work is very important for a purchasing manager to understand. The quality of the seal and the glass itself makes all the difference. Let’s look deeper into the mechanics.

How Do Vacuum Seal Containers with Pump Actually Work?

Are you confused about how a simple pump can keep food fresh? It might seem too easy. But the wrong mechanism can fail. This leads to air leaks and spoiled food, which means customer returns.

Vacuum seal containers use a pump, either manual or electric, to pull air out of the container through a special valve. This creates a low-oxygen space. A strong silicone seal on the lid keeps the air out. Less oxygen means bacteria and mold cannot grow easily, which preserves the food.

As a manufacturer, my team and I deal with the engineering of these lids every single day. The real magic is not just the pump; it is in the design of the valve and the quality of the silicone seal 1{#ref-1}. It is a simple idea, but making it reliable for thousands of uses is the hard part.

When a buyer like you is sourcing products, reliability is key. A seal that fails after three months is a bad product. Here is how the components work together.

Manual vs. Electric Vacuum Pumps: What’s theDifference?

You will see two main types of pumps offered with these containers. Both have a place in the market.

1. Manual Pumps: These are simple hand-operated pumps. The user places the pump on the lid’s valve and pumps it 5 to 10 times. This pulls the air out. They are great because they are portable, require no batteries or charging, and are often cheaper.

2. Electric Pumps: These are usually rechargeable (USB-C is common now). The user places the pump on the valve and presses a button. The pump runs for 10-15 seconds and stops automatically when a strong vacuum is reached. These are faster, easier to use, and often pull a stronger, more consistent vacuum. They are excellent for users with many containers or for people who may have trouble with a manual pump.

Here is a simple breakdown for your team:

| Pump Type | How it Works | Best For | Key Benefit |

|---|---|---|---|

| Manual Pump | User pumps by hand | Travel, camping, small kitchens | Simple, no power needed, lower cost |

| Electric Pump | Battery-operated (press button) | Busy homes, meal prep, users with low hand strength | Fast, easy, strong consistent vacuum |

The Science Behind Vacuum Sealing: How It Keeps Food Fresh Longer

Why does removing air even matter? Two main things spoil food: oxidation and microorganisms 2{#ref-2}.

- Oxidation: This is what happens when air touches the food. Oxygen breaks down fats, vitamins, and flavors. It makes nuts and crackers go stale. It makes fats in oils and meats go rancid. It turns cut apples brown.

- Microorganisms: This includes mold, yeast, and bacteria. Most of these tiny organisms need oxygen to breathe and multiply 3{#ref-3}.

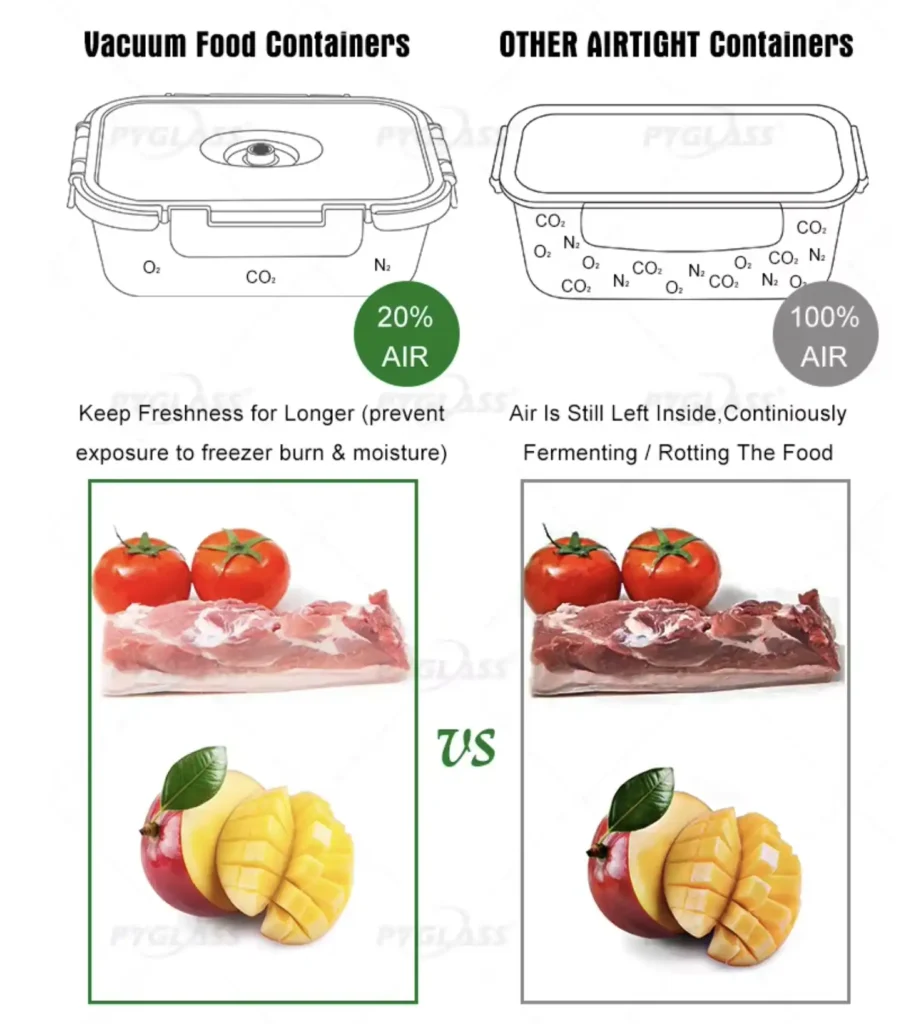

When you use a vacuum pump, you remove most of the oxygen (about 80-90%). This slows both of these processes way down. Oxidation almost stops. Mold and bacteria cannot grow easily. This is why food lasts so much longer. It is not the same as sterilization (like canning), but it is the best way to preserve fresh and dry foods in the fridge or pantry. It also stops freezer burn 4{#ref-4} by removing the air and moisture that form ice crystals.

Why Glass Makes a Difference in Vacuum Containers

You can find vacuum systems in plastic, but glass is the superior choice. As a manufacturer focused on safety and health, this is very important to me.

- Purity and Safety: Our borosilicate glass is non-porous 5{#ref-5}. It does not absorb food odors, flavors, or stains. Tomato sauce will not stain it. This is a big problem with plastic. More importantly, glass is chemically inert. It does not leak any chemicals into the food, ever. This is key for meeting FDA and LFGB standards 6{#ref-6}.

- Durability: Glass is rigid. When you pump the air out, a plastic container can slightly bend or warp under the pressure. Over time, this can weaken the plastic or the seal. Glass does not budge. It holds the vacuum perfectly.

- Eco-Friendly: Glass is 100% recyclable forever. Plastic degrades. Glass meets the “Greener” part of our mission and helps retailers meet their sustainability goals.

Are Vacuum Sealed Glass Containers Better for Food Storage?

You see plastic and glass options in every factory quote. Is glass really worth the extra cost and shipping weight for your inventory? Customers sometimes complain about heavy products.

Yes, glass is better for vacuum storage. Glass does not stain, absorb odors, or leak chemicals (like BPA) into food. It is safer for heating in the oven and microwave. It is also easier to clean and lasts longer. While heavier, its durability and health benefits make it a superior choice.

This is the most common question I get from purchasing managers. They must justify the higher cost per unit to their team. As someone who has run production lines for both, the answer is not just about function. It is about long-term value, safety, and brand reputation.

A plastic container that stains or warps looks cheap. A clear, pristine glass container looks like a quality, premium product.

Comparing Vacuum Seal Glass vs. Plastic Containers

When you are deciding what to stock, you have to balance all the factors. Buyers hate customer complaints. Glass containers lead to fewer complaints about staining, odors, or warping.

Here is a direct comparison I show my B2B clients:

| Feature | Borosilicate Glass | Standard Plastic |

|---|---|---|

| Health & Safety | Excellent. No chemicals (BPA-free, etc.) | Good (if BPA-free), but risk of microplastics. |

| Stains & Odors | Never stains or absorbs odors. | Stains easily (e.g., tomato sauce). Holds odors. |

| Heating | Excellent. Oven and microwave safe. | Microwave safe (sometimes). Never oven safe. |

| Durability | Lasts for decades. Does not scratch. | Scratches easily. Can warp in dishwasher. |

| Eco-Friendly | 100% recyclable and sustainable. | Difficult to recycle. Degrades over time. |

| WeightGas | Heavier. | Lighter. |

For a buyer like you, glass means a “safer” and “healthier” product that aligns with your customers’ values.

Can You Store Hot or Liquid Foods in Vacuum Glass Containers?

Yes, you can, but with one important rule.

For liquids like soups, sauces, or stews, vacuum sealing is fantastic. The strong seal is much more leak-proof than a standard snap lid. I often use them to transport soup for lunch.

For hot foods, you must let the food cool to room temperature before you put the lid on and vacuum seal it. Never seal hot, steaming food. There are two reasons:

1. The steam itself will create a (weak) vacuum as it cools. This can make the lid very hard to open.

2. More importantly, sealing hot food can trap heat and moisture. This can create a warm, low-oxygen space that anaerobic bacteria 7{#ref-7} (bacteria that don’t need oxygen) might like.

Always cool the food first. This is the safest method. Because our containers are borosilicate glass, they can handle the heat from the food easily without any risk of cracking.

Do Vacuum Sealed Containers Really Prevent Spoilage?

I want to be very clear and honest about this. They slow down spoilage. They do not stop it forever.

A vacuum-sealed container is not a magic time capsule. Perishable food like meat, fish, and dairy must still be stored in the refrigerator.

What they do is extend the life.

- In the pantry: They keep crackers, chips, and nuts crunchy for weeks. They keep coffee beans and tea leaves fresh. They stop pantry moths 8{#ref-8} from getting into flour and grains.

- In the fridge: They can make berries last 1-2 weeks instead of 3-4 days. They keep cheese from molding. They keep cut avocados green for days.

They work by stopping the things that cause spoilage: air, moisture, and pests.

What Types of Vacuum Containers Are Best for Different Needs?

Your customers all have different needs. You have meal preppers, bulk food shoppers, and large families. How can you stock the right mix of products for your stores? Choosing the wrong sizes leads to dead inventory.

For meal prep, choose small-to-medium stackable glass containers (0.5L to 1.5L). For bulk items like flour or coffee, large containers (2L+) are best. Always match the pump type (manual for portability, electric for high-volume use) to the customer’s lifestyle.

As a supplier, my job is to help my retail partners build the perfect product line. We do not just sell boxes. We provide a full solution. Offering the right shapes and sizes is critical for success.

Best Vacuum Seal Containers for Meal Prep and Leftovers

This is the fastest-growing market segment. These customers need containers that are easy to portion, store, and transport.

- Sizes: Look for sizes from 500ml (2 cups) to 1.5L (6 cups). These are best for single meals and side dishes.

- Stackability: This is a key innovation. Buyers ask me for this all the time. The lids must be designed to stack securely. This saves space in the fridge and in the pantry. This is a major pain point for consumers.

- Oven Safe: The glass must be borosilicate. Meal preppers want to take the container from the fridge and put it directly in the microwave or oven (after releasing the vacuum, of course). This “cook-and-serve” feature is a huge selling point.

Large Vacuum Sealed Containers for Bulk Food Storage

This customer buys food in bulk from stores like Costco. They want to protect their investment.

- Sizes: You need to offer large options, from 2L up to 5L.

- Benefit: These are for pantry staples. The key benefits are different. It is less about spoilage and more about preservation and protection.

* Coffee: Stops whole beans from losing flavor to oxidation.

* Nuts/Oils: Stops the healthy fats from going rancid.

* Flour/Grains: Creates an airtight barrier that stops pantry moths and other pests.

D. Brown Sugar: Stops it from turning into a hard brick.

Choosing the Right Vacuum Pump for Your Containers

A buyer should consider selling containers both individually and in sets. Sets should always include a pump.

- Starter Set: A 3-piece set with a manual pump is a great entry-level product.

- Premium Set: A 5-piece set with an electric pump appeals to the high-volume user.

Some brands use special, proprietary pumps. As a manufacturer, we can design a custom pump, but we find it is often better to use a universal valve design. This gives the consumer more flexibility.

Top 5 Recommended Glass Vacuum Seal Containers You Should Know

We have developed a wide range of products to meet these different needs. When our B2B clients ask for recommendations, these are the models I show them first. They are all made from high-borosilicate glass and use food-safe, high-grade seals.

1. The All-Rounder Set: This is our best-selling set. It includes various stackable sizes perfect for general-purpose meal prep and leftover storage.

2. The 10-Piece Wholesale Set with Manual Pump: This is ideal for retailers. It’s a complete “business in a box” that gives a family everything they need, including the simple, reliable manual pump.

3. The Premium Electric Pump Set: This set (also available at this link) features our one-touch electric pump. It’s a premium product for customers who want maximum freshness with minimum effort.

4. The 9-Piece Glass Lid Set: This is a key innovation. This set uses a glass lid with a silicone seal. It’s a 100% plastic-free food storage solution, which is a huge demand from eco-conscious consumers.

5.slyprc.com/product/vacuum-seal-containers-pump-best-vacuum-containers-freshness/)**: A perfect, low-cost entry point. It lets customers try vacuum sealing with a few containers and a manual pump before they commit to a larger set.

Are Vacuum Food Storage Containers Worth the Investment?

These premium containers are expensive. The price per unit is much higher than a simple plastic tub. Is the profit margin worth the high retail price?

Yes, they are worth the investment for both the consumer and the retailer. While the upfront cost is higher, they save consumers money by reducing food waste. Their durability (borosilicate glass) means they last for years. For retailers, they represent a high-value, high-margin product.

This is the main question a purchasing manager like you has to answer. It is all about the Return on Investment (ROI). I need to break down the true cost for my clients. The sticker price is not the true cost.

Cost vs. Benefit: Are Premium Glass Vacuum Containers Worth It?

The cost is higher. The shipping weight is higher, which increases logistics costs. I understand this. This is a pain point for buyers.

But the benefits create a strong case for that cost.

- For the End User: The average family throws away hundreds of dollars in spoiled food every year. If these containers make berries, cheese, and leftovers last 3x longer, they pay for themselves in just a few months.

- For the Retailer: You are not selling a disposable item. You are selling a durable, long-term solution. This commands a premium price. The cash margin on a $40 glass set is much higher than on a $10 plastic set. It also aligns with corporate sustainability goals 9{#ref-9}, which is a big focus for modern retailers.

I built this simple table to help my clients explain the value:

| Factor | Low-Cost Plastic Containers | Premium Glass Vacuum Containers |

|---|---|---|

| Initial Cost | Low | High |

| Lifespan | 1-2 years (stains, warps) | 10+ years (durable glass) |

| Food Waste | High (food spoils quickly) | Low (food lasts 3-5x longer) |

| Long-Term Cost | High (constant replacement + food waste) | Low (buy once + food savings) |

| Brand Image | Disposable, low quality | Premium, safe, sustainable |

Durability and Reusability: How Long Do They Last?

A plastic container is almost disposable. It scratches. It stains. It warps in the dishwasher. The lid tabs break.

Our borosilicate glass containers are designed to last a lifetime. The glass itself will not degrade. It can be put in the dishwasher, freezer, microwave, and oven (up to 400°C) thousands of times.

The only “wear” part is the silicone seal and the valve. As a quality-focused manufacturer, we use high-grade, food-safe silicone. We test our seals for thousands of cycles. A good seal should last for many years. This is a key quality control point you should ask any supplier about.

Certifications and Safety: What to Check Before Buying

This is the most critical point for any professional buyer. A product that fails compliance is a huge risk. It can lead to recalls, fines, and damage to your brand.

When I talk to buyers, I lead with our compliance. It provides immediate peace of mind. Here is what you must ask for:

- FDA: This is the minimum US standard for any material that touches food.

- LFGB: This is the German/EU standard. It is much stricter than FDA and tests for more chemicals. The “knife and fork” symbol is a sign of high quality.

- DGCCRF: This is the French standard, also very strict.

- BPA-Free: This applies to the lid. The plastic parts of the lid and the pump must be certified BPA-free.

Any factory you work with should provide you with the full, recent test reports for all these standards. If they cannot, that is a major red flag.

Where to Buy the Best Glass Vacuum Containers Direct from the Factory?

Finding a good supplier in Asia is difficult. You face constant risks of poor quality, missed deadlines, or compliance failures. How do you find a real partner?

Look for suppliers with strong factory audits (like ISO9001, BSCI) and proven product compliance (FDA, LFGB). A good partner is a manufacturer, not a trading agent. They offer OEM/ODM services, design support, and flexible logistics. Direct-from-factory suppliers like PYGLASS offer better prices and customization.

This is where I can finally talk directly about my company. I built PYGLASS from the ground up. I started 15 years ago because I saw buyers struggling with these exact problems. I wanted to build a factory that solves these pain points.

What to Look for in a Reliable Manufacturer orSupplier

When you are auditing a new factory, you need to look for proof, not just promises.

- Factory Audits: Ask for their ISO9001 10{#ref-10} (for quality management) and BSCI (for social compliance) reports. We are proud to be audited by major retailers like Walmart and Costco.

- Certifications: Ask for the product test reports (FDA, LFGB) from this year.

- Specialization: Do they specialize in borosilicate glass? Many factories use cheaper soda-lime glass, which can crack with temperature changes. We only work with high-borosilicate glass.

- Communication: Do they give you direct, clear answers? As a buyer, you do not have time for vague replies. You need a partner who is professional.

OEM/ODM Options for Retailers and Distributors

A good supplier should be a partner in product development.

- ODM (Original Design Manufacturer): You can choose from our 100+ existing molds (like the ones I listed above) and we will put your brand and custom packaging on them. This is fast and low-cost.

- OEM (Original Equipment Manufacturer): You have a new idea. Maybe a new lid design or a unique shape. Our R&D team will work with your designers to build it. We provide the “Engineering & Design Support” that smart buyers look for.

How PYGLASS Helps Buyers Get Certified, Custom Vacuum Containers

My goal is to make your job as a purchasing manager easier. We are not just a vendor; we are your strategic partner in China.

- We Solve Compliance: We are fully certified (FDA, LFGB, DGCCRF) and audited (ISO9G01, BSCI). The risk is gone.

- We Solve Quality & Breakage: We own our 200,000㎡ manufacturing base. We control 100% of the quality, from raw materials to final packaging. We have developed special, protective packaging solutions to reduce breakage during transport.

- We Solve Innovation: We specialize in high-borosilicate glass. Our R&D team can help you design the stackable, leak-proof, and easy-to-clean products your customers want.

- We Are the Partner: You will talk directly to my team. We provide clear timelines and updates. We aim for a long-term relationship, not a one-time order.

Our mission is “Safer, Healthier, Greener.” This is what we build into every product we make.

Conclusion

So, do vacuum seal glass containers work? Absolutely. They are one of the best investments a consumer can make to save money and reduce food waste. They keep food fresh 3-5 times longer by removing air. Glass is the best material because it is safer, healthier, and more durable than plastic.

For a purchasing manager, the product is only half the story. The most important step is choosing a certified and reliable supplier. A good factory partner provides quality, compliance, and innovation. This ensures the products you put on the shelf will be successful.

Footnotes

1. Details on food-grade silicone seals and their importance. ↩︎

2. The science of how oxygen and microbes spoil food. ↩︎

3. Learn about the microorganisms that cause food spoilage. ↩︎

4. Find out how removing air prevents freezer burn. ↩︎

5. Explore the properties and benefits of borosilicate glass. ↩︎

6. A comparison of FDA and LFGB food contact material standards. ↩︎

7. Understand the risks of bacteria that grow without oxygen. ↩︎

8. Tips on how airtight seals protect grains from pests. ↩︎

9. How sustainable products help businesses meet their goals. ↩︎

10. Learn how ISO 9001 ensures consistent quality standards. ↩︎