Your peak season is approaching, and your current supplier just admitted they cannot meet the deadline. This delay doesn’t just cost money; it ruins your reputation with retailers and leaves shelves empty. Finding a partner who can actually deliver what they promise is the only way to protect your supply chain.

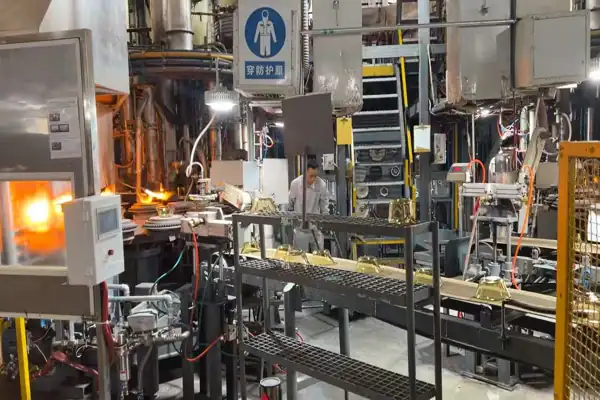

To evaluate true capacity, you must look beyond surface-level claims and calculate the net yield by subtracting defect and breakage rates from gross output. Verify the furnace melting capacity in tons per day (TPD), as this is the hard physical limit for any glass production. A reliable manufacturer should maintain an Overall Equipment Effectiveness (OEE) of 75% to 85%. At PYGLASS, we ensure our 200,000㎡ facility operates with transparent KPIs, allowing buyers to verify that our daily output matches their high-volume requirements without compromising on international safety standards like FDA or LFGB.

Choosing a supplier is often a leap of faith, but in the glassware industry, it should be a calculation. We have seen many purchasing managers like you get burned by “paper capacities” that vanish when the heat is on. Understanding the mechanics of a glass factory—from the furnace pull rate to the speed of the annealing lehr 1{#ref-1}—is the only way to ensure your containers, bakeware, or bowls arrive on time. If you want to stop guessing and start measuring, you need to know which specific metrics reveal the truth about a factory’s ability to scale.

How can I verify the daily output claims of a glass factory?

We often see sales teams quote “maximum theoretical capacity” to impress buyers, but our production floor tells a different story. In our Zibo facility, we focus on what we can actually ship, not just what the machines can theoretically spin out in a perfect world.

Verifying daily output requires a deep dive into historical production logs and a comparison between gross pull and net yield. You should ask for the “Daily Production Report” from the previous month to see the actual number of shippable units produced versus the initial machine count. A factory claiming 100% efficiency is hiding something; a realistic and healthy output usually sits between 80% and 88% after accounting for quality inspections, mold changes, and necessary maintenance downtime. This transparency is the only way to guarantee your order doesn’t face unexpected bottlenecks.

Understanding Theoretical vs. Realized Capacity

In my 15 years of managing glass production, I have learned that the “Theoretical Capacity” is a dangerous number to rely on. It assumes that every machine runs at top speed 24/7 without a single defect. Realized capacity, however, is the actual number of high-quality vidrio borosilicato 2{#ref-2} containers that pass our final inspection and are ready for your warehouse.

When you audit a supplier, you need to distinguish between these two. If a factory has 10 lines and each can produce 10,000 units a day, they might claim a capacity of 100,000 units. However, if their defect rate is 15% and they spend 4 hours a day on mold changes for different SKUs, their real capacity is closer to 70,000 units. We always suggest that buyers look at the net yield 3{#ref-3}. This is the only number that impacts your delivery date.

Key Metrics for Capacity Evaluation

To get an accurate picture, we use several KPIs on our shop floor. You should ask your potential suppliers for these specific data points during your next visit or video audit.

| Metric | Definition | Importance for the Buyer |

|---|---|---|

| Gross Pull | The total weight of glass melted and formed. | Shows the raw power of the furnace. |

| Net Yield | The final count of products that pass QC. | Tells you exactly how many pieces are shippable. |

| OEE | Overall Equipment Effectiveness (OEE) 4{#ref-4} | Measures the overall health and efficiency of the factory. |

| Downtime % | Time lost to repairs or setup changes. | High downtime suggests aging machinery or poor management. |

The Impact of Shift Management

Our engineers have found that production consistency often fluctuates between shifts. A factory might have a stellar day shift but a struggling night shift. When verifying output, ask how many shifts the factory runs. At our 200,000㎡ base, we run three continuous shifts to keep the furnaces at an optimal temperature. If a supplier only runs one or two shifts, their furnace efficiency drops, and they may struggle to catch up if they fall behind on your schedule. Consistent, 24-hour operation is a hallmark of a professional high-volume manufacturer.

What questions should I ask about their furnace and production line capacity?

The furnace is the heart of any glass operation, and if it stops, the whole factory dies. At our manufacturing base, we treat our furnaces as our most critical assets because they dictate the hard limit of what we can produce for our global partners.

You must ask about the furnace “Pull Rate” in tons per day (TPD) and the age of the furnace lining. A standard high-volume furnace should handle between 150 and 600 tons of glass daily. Additionally, ask if they use continuous melting or batch melting; continuous melting is essential for the large-scale, consistent production required by retail chains like Walmart or Costco. If the furnace capacity is lower than your total order weight divided by the production days, the factory will inevitably fail to meet your deadline.

Continuous Melting vs. Batch Melting

In the world of glassware, the melting process determines both volume and quality. Our facility utilizes continuous melting furnaces because they provide a steady stream of molten glass, ensuring that every container has the same resistencia al choque térmico 5{#ref-5} and clarity.

For smaller, custom orders, some factories use batch melting. While this is flexible, it is inefficient for the high-volume needs of a purchasing manager like Jacky. If you are looking for 50,000 glass meal prep containers, you want a factory using continuous melting capacity 6{#ref-6}. This process reduces the risk of “stones” or bubbles in the glass, which are common quality issues when furnaces are frequently started and stopped.

Identifying Production Bottlenecks

Even the fastest furnace can be slowed down by “Cold End” bottlenecks. Our team analyzes every step of the process to ensure a smooth flow. You should ask about the capacity of the following stages:

- Forming Machines: Are they using Individual Section (IS) machines 7{#ref-7} or manual blowing? High-speed automated IS machines are required for consistency.

- Annealing Lehrs: This is where glass is cooled slowly to remove internal stress. If the lehr is too short or too slow, it limits the speed of the entire production line.

- Automatic Inspection: Does the factory rely on human eyes alone, or do they have optoelectronic inspection machines? Automated inspection is faster and much more reliable for high-volume orders.

Equipment Capability Comparison

To help you evaluate different suppliers, we have put together this comparison of equipment standards.

| Equipment Type | Low-Tier Factory | PYGLASS Standard |

|---|---|---|

| Tipo de horno | Small Batch / Pot Furnaces | Large Continuous Melting (TPD >200) |

| Forming Process | Manual or Semi-Auto | Fully Automated IS Machines |

| Inspección | 100% Manual | Integrated AI Vision + Manual Spot Check |

| Certificaciones | Basic Local Standards | ISO9001, BSCI, Walmart, Costco |

By asking about these specific hardware components, you can quickly tell if a factory is equipped to handle a professional retail rollout or if they are better suited for small, artisanal gift shop orders.

How do I ensure the manufacturer can handle my peak season orders without delays?

We know that missing a Christmas or Back-to-School launch is a nightmare for category managers. Our project management team spends months planning for peak seasons to ensure our regular clients never have to compete for “oven time” during the busiest months of the year.

To secure your peak season delivery, ask the manufacturer for their “Capacity Utilization Rate” during the same period last year. A well-managed factory should keep about 15% to 20% of their capacity as a “buffer” for urgent orders or unexpected delays. You should also demand a detailed production timeline that includes lead times for raw materials like silica sand and soda ash. If a supplier is already running at 95% capacity in July, they will almost certainly have a backlog by the time your September peak order arrives.

The Importance of Buffer Capacity

In my experience, the most successful partnerships are built on “buffer capacity.” We never book our factory to 100% theoretical capacity. Why? Because machines break, power can flicker, and raw material shipments can be delayed by a day. By maintaining a buffer, we can absorb these small shocks without pushing back your ship date.

When interviewing a supplier, ask: “What happens if a machine goes down for 48 hours? How do you make up that time?” If they don’t have a clear answer involving spare lines or overtime shifts, your order is at risk. A factory that is always “fully booked” is a factory that is one small mistake away from a catastrophic delay.

Raw Material Resilience

Capacity isn’t just about machines; it’s about having the “ingredients” ready. For our borosilicate glass, we maintain strategic reserves of high-purity silica sand and borax. In 2026, supply chain volatility is still a factor. We recommend checking if your supplier has long-term contracts with their raw material providers.

- Silica Sand: The primary component. Local sourcing is better for stability.

- Soda Ash & Borax: These act as fluxing agents. Prices can fluctuate wildly.

- Cullet (Recycled Glass): Using cullet improves furnace efficiency and aligns with the “Greener” mission of brands like PYGLASS.

Peak Season Planning Checklist

Use this checklist when negotiating with a supplier for your Q3 and Q4 inventory.

| Checklist Item | Requirement | Why it Matters |

|---|---|---|

| Confirmed Lead Time | 35-45 Days | Allows for shipping buffers. |

| Mold Preparation | 2 Weeks Ahead | Prevents delays on the production start date. |

| Labor Stability | >90% Retention | Ensures experienced operators are on your line. |

| Energy Redundancy | Dual-Fuel Furnaces | Protects against local power outages. |

Our managers work closely with buyers to lock in furnace space months in advance. This capacity utilization rate 8{#ref-8} approach is what separates a professional purchasing manager from someone who is just buying off the shelf.

What signs indicate a factory is outsourcing my order to smaller workshops?

This is the “dark secret” of the industry that we always warn our clients about. When a factory takes an order that exceeds its true capacity, they often “sub-contract” it to smaller, unregulated workshops. This is a massive risk to your brand’s safety and compliance reputation.

Red flags for outsourcing include inconsistent glass clarity, varied weight between pieces of the same SKU, and different styles of packaging in a single shipment. If you request a live video tour of your production run and the factory makes excuses, or if the “Quality Control” stamps look different across several boxes, your order has likely been split across multiple sites. This practice bypasses the strict ISO9001 and BSCI audits that you rely on to ensure product safety and ethical labor practices.

The Danger of Inconsistent Quality

At PYGLASS, we control every square meter of our 200,000㎡ base because we know that “Batch Identity” is everything. When a factory outsources, they lose control over the glass formula. One workshop might use lower-grade sand, while another might skimp on the annealing time. The result? Some of your containers might be safe, while others might shatter in a customer’s oven.

For a Purchasing Manager like Jacky, this is a legal nightmare. If a batch fails FDA or LFGB testing 9{#ref-9} because it was made in a workshop without proper controls, the entire shipment must be recalled. We’ve seen companies lose millions because they trusted a supplier who secretly outsourced to meet a deadline they should never have accepted.

How to Spot the “Middleman” Factory

Some companies pose as manufacturers but are actually just trading houses with a small assembly line. They use fancy showrooms to hide the fact that they don’t own the furnaces. Here is how our engineers suggest you sniff them out:

- Ask for the Daily Production Report 10{#ref-10}: A real manufacturer can show you real-time data from their furnace control room. A middleman will have no access to this.

- Check the Electricity Bill: This sounds extreme, but for a factory our size, energy is our biggest cost. A massive factory with a tiny electricity bill is a ghost factory.

- Analyze the Glass Color: Borosilicate glass should have a consistent, slight tint (usually very clear or slightly amber/green depending on the formula). If your shipment has multiple “shades” of glass, it came from multiple furnaces.

Red Flags vs. Green Flags in Production

| Característica | Red Flag (Possible Outsourcing) | Green Flag (In-House Production) |

|---|---|---|

| Production Photos | Generic or “Marketing” photos. | Photos of your specific mold and packaging. |

| QC Reports | Vague, one-page summaries. | Detailed reports with thermal shock and stress tests. |

| Comunicación | Delays in answering technical questions. | Immediate answers from on-site engineers. |

| Embalaje | Slight variations in box color/font. | Identical, high-quality branded packaging. |

We take great pride in our transparency. When we say a product is “Made by PYGLASS,” it means it was melted, formed, and inspected under our roof in Zibo. This is the only way we can stand behind our slogan: Safer, Healthier, Greener.

Conclusión

Evaluating the true capacity of a glassware manufacturer requires looking past the sales pitch and into the heart of the factory—the furnace, the metrics, and the management. By focusing on Net Yield, TPD pull rates, and buffer capacity, you can identify partners who will actually deliver on time. Avoid the risks of outsourcing by demanding transparency and verifying batch consistency. At PYGLASS, we believe that high-quality glass is a responsibility, and that starts with a production line you can trust. Ready to secure your next high-volume order with a factory that values your schedule as much as you do?

Notas a pie de página

1. Technical explanation of how the annealing lehr stabilizes glass by relieving internal stresses. ↩︎

2. Overview of borosilicate glass properties and its diverse applications in industrial glassware. ↩︎

3. Understanding the definition and calculation of net yield in a manufacturing production environment. ↩︎

4. Comprehensive guide to measuring and improving Overall Equipment Effectiveness (OEE) in factories. ↩︎

5. The science behind thermal shock resistance and how it prevents glass from shattering. ↩︎

6. Insights into industrial furnace melting capacity and its impact on large-scale glass production. ↩︎

7. History and technical evolution of Individual Section (IS) machines in automated glass forming. ↩︎

8. Detailed explanation of capacity utilization rate and its importance for business efficiency. ↩︎

9. International safety standards and testing requirements for materials in contact with food. ↩︎

10. Professional templates and best practices for creating effective daily manufacturing production reports. ↩︎