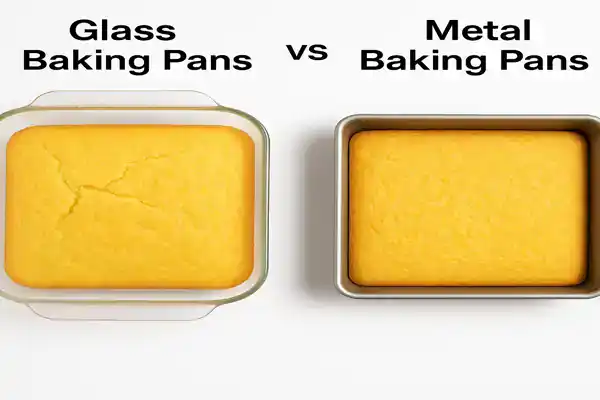

¿Está cansado de resultados de horneado desiguales que merman sus beneficios? La elección entre moldes de cristal o de metal puede parecer insignificante, pero afecta directamente a la calidad del producto, la eficiencia de la producción y los costes operativos. Una elección equivocada genera residuos, frustración del personal y clientes decepcionados.

La principal diferencia radica en cómo transfieren el calor: Las sartenes de metal son conductoras, se calientan y enfrían rápidamente para obtener bordes crujientes y un dorado uniforme. Las de cristal son aislantes: se calientan lentamente pero retienen el calor durante más tiempo. Ideales para guisos y platos ácidos, pero arriesgadas para pasteles delicados.

Con más de 15 años en el sector de la fabricación de vidrio, he visto a panaderías y marcas de alimentación enfrentarse a esta decisión. La elección del material de horneado adecuado no tiene que ver con el coste inicial, sino con la creación de una línea de producción estable y eficiente que ofrezca un rendimiento constante y de alta calidad. Esta guía es para usted -el director de compras o el propietario de una panadería- que necesita tomar la decisión más inteligente posible. Comencemos.

¿Por qué todo empieza por cómo gestionan el calor los utensilios para hornear?

¿Sigue luchando contra los bordes quemados y los centros poco hechos? Este problema tan común a menudo se reduce a una cosa: cómo maneja el calor su sartén.

El vidrio es un aislante: se calienta lentamente y retiene el calor. El metal es un conductor: se calienta y se enfría rápidamente. Este comportamiento térmico influye directamente en el tiempo de horneado, el dorado y la textura final.

Como responsable de compras, no sólo está comprando una sartén, sino el control de una de las variables más importantes de su línea de producción: el calor. Desglosémoslo en tres sencillos pero poderosos principios científicos que he explicado a cientos de clientes a lo largo de los años.

Conducción del calor: A qué velocidad se transfiere el calor

Conducción del calor 1{#ref-1} es la rapidez con la que el calor atraviesa un material. Por ejemplo, cuando un poste de metal está más frío que uno de madera en un día de invierno, la mano se calienta más rápidamente.

- Sartenes metálicas (especialmente de aluminio): Excelentes conductores del calor que transfieren eficazmente el calor del horno a la masa. Perfectos para productos que requieren una fermentación y cuajado rápidos, como pasteles y pan. El calor rápido garantiza agentes leudantes 2{#ref-2} activar antes de que se forme la corteza.

- Cacerolas de cristal: Calientan más despacio y con más suavidad. Es un inconveniente para algunos productos, pero una gran ventaja para otros, como veremos más adelante.

Retención del calor: El efecto "inercia" tras la cocción

¿Cuánto tiempo permanece caliente una sartén después de sacarla del horno?

- Sartenes de metal: Enfriar rápidamente. Esto ayuda a detener el proceso de horneado inmediatamente y aumenta el tiempo de respuesta, lo que resulta ideal para la eficiencia comercial.

- Cacerolas de cristal: Retiene el calor durante más tiempo. Ese calor prolongado mantiene los productos cociéndose incluso después de salir del horno. Esto puede resecar un bizcocho, pero en el caso de una lasaña o unas patatas fritas, mantiene los alimentos calientes y listos para servir.

Reactividad del material: Impacto del sabor

¿Afecta el material al sabor de los alimentos?

- Sartenes de metal: Especialmente el aluminio no tratado, puede reaccionar con alimentos ácidos (como tomates, cítricos o rellenos de frutas). Esto puede provocar sabores desagradables o decoloración de la sartén. Muchas sartenes metálicas modernas están recubiertas de antiadherente o anodizado para reducir este riesgo 3{#ref-3}.

- Cacerolas de cristal: Inerte y no reactivo. Seguro para hornear y almacenar alimentos ácidos sin afectar al sabor ni a la seguridad.

Comprender estos tres pilares -conducción, retención y reactividad- sienta las bases para elegir el molde adecuado para su línea de productos.

| Propiedad | Recipientes de vidrio para hornear (aislante) | Recipientes metálicos para hornear (conductores) |

|---|---|---|

| Conducción del calor | Lento y suave | Rápido y eficaz |

| Retención del calor | Excelente (retiene el calor) | Inferior (se enfría rápidamente) |

| Reactividad del material | No reactivo (resistente a los ácidos) | Puede reaccionar con los ácidos (a menos que esté recubierto) |

¿Son los moldes de metal el verdadero caballo de batalla para la velocidad y la consistencia?

¿Necesita producir cientos de galletas o brownies al día? En la panadería comercial, la consistencia lo es todo, y su molde es una parte fundamental de ese proceso.

Sí, los utensilios de metal, especialmente los de aluminio claro, son el caballo de batalla de la mayoría de las panaderías comerciales. Se calienta rápidamente, hornea de manera uniforme y se enfría con rapidez, lo que garantiza una calidad constante del producto y la máxima productividad.

Cada vez que paso por una panadería comercial, las sartenes metálicas dominan las estanterías. No es casualidad. Funcionan excepcionalmente bien en entornos de gran volumen en los que el tiempo, la consistencia y la durabilidad impulsan la rentabilidad. He aquí por qué:

Calefacción uniforme Champion

El aluminio distribuye el calor de forma uniforme y rápida. Elimina los puntos calientes, enemigos del horneado uniforme. Esto reduce directamente el desperdicio de producto y aumenta el control de calidad 4{#ref-4}.

Imprescindible para:

- Pasteles de hojas: Tapas planas, sin rebordear

- Galletas: Dorado uniforme en toda la bandeja

- Brownies: Bordes limpios y nítidos con centros pastosos

Rapidez y eficacia

Tiempos de precalentamiento más rápidos = horneados más rápidos

Enfriamiento más rápido = recarga más rápida

Todo ello combinado puede proporcionarle varias tandas extra al día, sin necesidad de comprar más hornos.

Durabilidad en cocinas comerciales

Las cacerolas metálicas resisten caídas, apilamientos y fregados industriales. Aunque se abollen, siguen funcionando. Comparadas con las de cristal, son más indulgentes y presentan menos riesgo de rotura o lesiones en situaciones de mucho trabajo. cocinas industriales 5{#ref-5}.

¿Es el vidrio para hornear una herramienta versátil para la exposición y los artículos especiales?

¿Algunos de sus productos van directamente del horno a la vitrina o a la mesa del comedor? En ese caso, los utensilios para hornear se convierten en algo más que un simple utensilio: forman parte de la presentación final.

Absolutamente. Los recipientes de cristal son muy versátiles. Es ideal para recetas ácidas, presentaciones elegantes y platos que se benefician de un calor lento y constante. No es reactivo, mantiene bien el calor y queda bonito en la mesa.

He trabajado con cafeterías y panaderías boutique que prefieren los recipientes de cristal por su atractivo visual y sus productos especiales. Funciona mejor en situaciones en las que el metal simplemente no brilla.

Ideal para conservación en caliente y presentación

Gracias a sus propiedades aislantes, el vidrio mantiene el calor durante más tiempo que el metal. Ideal para:

- Cazuelas y gratinados: Manténgase caliente más tiempo en las colas del bufé

- Patatas fritas y pasteles de frutas: Mantener su textura caliente para el servicio

- Tartas: Permite el control visual del color de la corteza

Perfecto para platos ácidos

Piense en tartas de limón y merengue, lasaña de tomate y platos marinados en vinagre.

El vidrio es completamente no reactivo, por lo que es perfecto para platos ácidos 6{#ref-6}:

- Sin sabor metálico

- Sin decoloración

- Sin problemas de seguridad alimentaria

Transparencia para el control visual de la cocción

Poder ver el fondo de su tarta o pastel mientras se hornea elimina las conjeturas y garantiza ese acabado dorado. Este transparencia para el control visual del horneado 7{#ref-7} es una ventaja clave del vidrio.

¿Cómo combinar la sartén adecuada con sus productos estrella?

Al igual que se elige el cuchillo adecuado para cada trabajo, se necesita la sartén adecuada para cada producto.

Para velocidad, elevación y crujido, utilice metal. Para un horneado suave, una preparación a prueba de ácidos y un servicio elegante, utilice vidrio.

Ideal para sartenes metálicas:

- Magdalenas y cupcakes: Subida rápida, bordes afilados

- Galletas: Fondos uniformes, sin quemaduras

- Brownies: Crujiente por fuera, masticable por dentro

Ideal para cacerolas de cristal:

- Tartas de frutas: Ver color de la corteza, sin reacción ácida

- Guisos: Permanece caliente más tiempo, del horno a la mesa

- Puddings/ natillas: Horneado suave para texturas blandas

Pregunta frecuente: ¿Se puede hornear un pastel en un molde de cristal?

Sí, pero no es ideal para la repostería comercial. El vidrio se calienta más lentamente y retiene el calor durante más tiempo. Esto aumenta el riesgo de bordes quemados y centros densos.

Si se utiliza un molde de cristal para hornear un pastel:

- Reduzca la temperatura del horno en 25°F (15°C)

- Añadir 5-10 minutos de horneado

- Dejar enfriar el pastel más tiempo antes de desmoldarlo

| Categoría de productos | Cacerola recomendada | Razón |

|---|---|---|

| Tartas de capas | Metal ligero | Calentamiento rápido para una subida adecuada |

| Cookies | Metal ligero | Horneado uniforme, sin exceso de dorado |

| Brownies | Metal ligero | Bordes crujientes, centros blandos |

| Pasteles de frutas | Vidrio | Transparencia + resistencia a los ácidos |

| Lasaña/Cacerola | Vidrio | Retiene el calor, agradable a la vista |

| Budines y natillas | Vidrio | Cocción suave, evita el cuajado |

¿Realmente influyen el color y el recubrimiento en los resultados de horneado?

Material aparte, la sartén color y superficie también marcan una gran diferencia.

Sí. Las sartenes oscuras absorben más calor y hornean más rápido. Las sartenes claras reflejan el calor y hornean más suavemente. Los revestimientos de la superficie afectan a la liberación, el dorado y la vida útil.

Ciencia del color: Oscuridad frente a claridad

| Pan Color | Comportamiento térmico | Mejores casos de uso |

|---|---|---|

| Acabado oscuro | Absorbe el calor rápidamente | Pan crujiente, bordes crujientes |

| Acabado claro | Refleja el calor | Pasteles delicados, dorado uniforme |

Diferencias de revestimiento:

- Revestimiento antiadherente 8{#ref-8}: Fácil de soltar, se desgasta con el tiempo

- Aluminio en bruto: Duradero pero requiere engrase

- Superficie de cristal: Suave, naturalmente antiadherente con un ligero engrasado

Consejo: Un cliente redujo las quejas en 40% solo con cambiar las sartenes oscuras por las plateadas. A veces, el color por sí solo resuelve el problema.

¿Cuáles son los 4 factores más importantes en la compra de utensilios de repostería a granel?

Más allá del rendimiento, debe pensar como un directivo.

No está comprando sólo equipos, sino un retorno de la inversión a largo plazo. Evalúe cuatro aspectos: Coste, Eficiencia, Durabilidad y Mantenimiento.

| Factor | Recipientes de cristal para hornear | Batería de metal |

|---|---|---|

| Coste de compra | Mayor inversión inicial, mayor vida útil | Menor coste inicial, puede sustituir a más |

| Velocidad de producción | Tiempo de cocción/enfriamiento más lento | Cocción y recarga rápidas |

| Durabilidad | No se deforma, pero es frágil | Resistente, pero puede abollarse/rayarse |

| Facilidad de limpieza | Fácil de limpiar, apto para lavavajillas | Puede requerir lavado o cuidado a mano |

Para volumen, velocidad y consistencia: apuesta por el metal.

Para la presentación, la integridad del sabor y la resistencia a la acidez: opte por el vidrio.

Consejo final: ¿Cómo crear una cartera de productos de repostería más inteligente?

No se trata de una decisión de "elige uno y olvídate del otro".

Las panaderías más inteligentes aplican una estrategia mixta.

La regla de inversión 80/20:

- 80% Batería de metal para hornear: Utilizar para productos básicos de alta frecuencia como pasteles, galletas y pan

- 20% Recipiente de cristal para hornear: Utilícelo para tartas, guisos, pudines o para servir al horno

Esto le proporciona la velocidad del metal y la delicadeza del cristal, sin concesiones. Construir un estrategia mixta para hornear 9{#ref-9} garantiza que esté preparado para cualquier producto al tiempo que maximiza su ROI a largo plazo 10{#ref-10}.

Conclusión

Elegir entre recipientes de cristal o de metal para hornear es algo más que una preferencia: es una decisión estratégica.

Las sartenes metálicas le ofrecen rapidez, resistencia y estandarización para el horneado diario de alto rendimiento.

Las bandejas de cristal le ofrecen protección del sabor, presentación y flexibilidad para productos de primera calidad o ácidos.

No elijas bando, elige emparejamiento inteligente. La sartén adecuada para cada tarea le ofrece una mejor calidad del producto, menos residuos, clientes más satisfechos y mayores beneficios.

Notas a pie de página

1. Una comparación en profundidad de cómo conducen el calor los distintos materiales para hornear, incluidos el vidrio y el metal. ↩︎

2. Conozca la ciencia de los leudantes químicos y cómo hacen subir los productos de panadería. ↩︎

3. Descubra qué son los utensilios de cocina anodizados duros y cómo evitan la reactividad con los alimentos ácidos. ↩︎

4. Orientaciones oficiales de la FDA sobre los principios HACCP para garantizar la seguridad alimentaria y el control de calidad. ↩︎

5. Una guía completa para diseñar distribuciones eficientes y seguras para cocinas comerciales. ↩︎

6. Una lista de alimentos ácidos comunes y por qué los utensilios de cocina no reactivos son importantes para ellos. ↩︎

7. Explore una colección de utensilios de cristal de alta calidad perfectos para controlar visualmente el progreso de la cocción. ↩︎

8. Una visión general de los utensilios de cocina antiadherentes, explicando su seguridad, tipos e instrucciones para su correcto cuidado. ↩︎

9. Explore una amplia selección de utensilios de repostería para crear una cartera versátil para cualquier necesidad comercial. ↩︎

10. Una guía clara que explica cómo calcular el rendimiento de la inversión en las compras de las empresas. ↩︎