Professional manufacturer and exporter for high borosilicate glassware in China!

Amplia experiencia de trabajo con marcas famosas

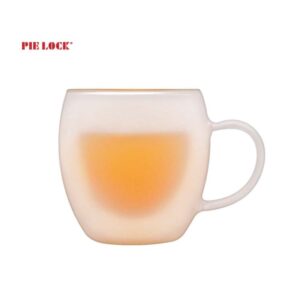

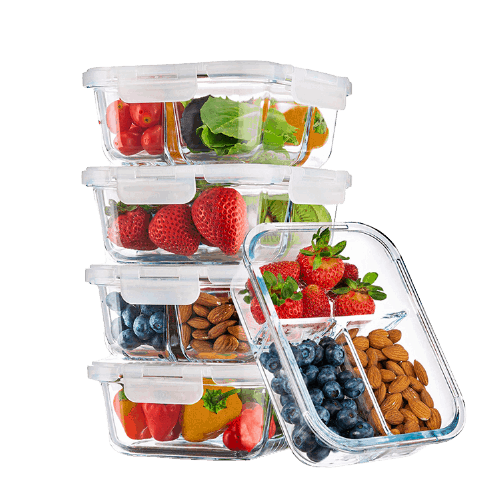

Featured Products

Fabricante y exportador profesional de cristalería de borosilicato de alta calidad en China.

20 years experience,cover 500000²,46 production machines,16 engineers!

Our factory pass ISO9001, Walmart, Sedex, AVON, BSCI factory audit.

Our product pass FDA, LFGB, CE from SGS and BV.

Full product category in good quality.

Quick delivery time and great service.

Cooperation with the world market

7*24 hour global service

Dear Customers,

Suministramos OEM / ODM servicio: podemos hacer logotipo en la tapa de color vivo se puede hacer Embalaje personalizado Tres forma, más de diez tamaños para la elección. Si tiene necesidades diferentes, póngase en contacto con nosotros para obtener el presupuesto correspondiente.

We develop the desired products for our customers by using our technology and equipment and following the requirements of our customers. We have developed many kinds of products for the pressed borosilicate glass products in a wide range of shapes, such as microwave oven trays, microwave oven glassware, door glass for washing machines, and other pressed glass products, etc.

The company performs the feasibility evaluation for each drawing or product furnished by our customer. It then communicates the evaluation opinion with the customer in a bid to reach a consensus. The development schedule for the product, such as mold manufacturing, test product, etc. then decided. The company confirms the drawings or products furnished by the customers, carries out the mold design and manufacture and develops the facility related to upgrading production equipment.

La empresa inicia la producción piloto y realiza mejoras continuas, y finalmente entrega la muestra al cliente para su confirmación. Una vez satisfechos todos los requisitos del cliente, la empresa inicia la producción en serie del producto según la orden de compra del cliente.

7.Horno de recocido

We are both trading and manufacturer.

Sí, mucho apoyo

1000 unidades o 1000 juegos de cada artículo.

Podríamos enviar 1-3pcs muestras gratuitas para que usted compruebe la calidad y la carga recoger.

Sí, por supuesto, somos fábrica de vidrio, podemos abrir nuevos moldes de vidrio, así como insertar papel, logotipo, embalaje según el requisito del cliente.

Hemos pasado la FDA, LFGB, DGCCRF certificados, así como las auditorías de algunas de las empresas famosas como Walmart, BSCI, WCA, Avon, etc. Tenemos nuestro propio QC para comprobar las producciones en masa en la fábrica. Todos los productos pueden pasar las pruebas SGS, BV y TUV.

How is High Borosilicate Glassware processed?

1. Silica sand, borax and other raw materials are mixed proportionally and then we use an electronic scale to weigh each raw material to ensure that the mixing ratio satisfies technical requirements.

2. At the temperature as high as 1,600℃, the raw materials are melted together. The precise control on the liquid surface is used together with the automatic feeding system to ensure the process stability of the melting and clarification. Moltenglass feeding systems and multiple-station press machines are used to produce various products.

3. Which are fire-polished to eliminate the un-smoothness caused by the parting line of a mould/dire. Products are annealed in an annealing lehr to eliminate their internal stress and ensure their physical properties.

4. Products are inspected according to the quality standard of the company or customers’ requirements, and then packed, stored and shipped with the package complying with the specification by the customer.