Glass food containers may look simple, but behind every clear and smooth surface is a highly precise and controlled production process. Understanding how they are made reveals why glass remains one of the safest and most sustainable packaging materials in the world.

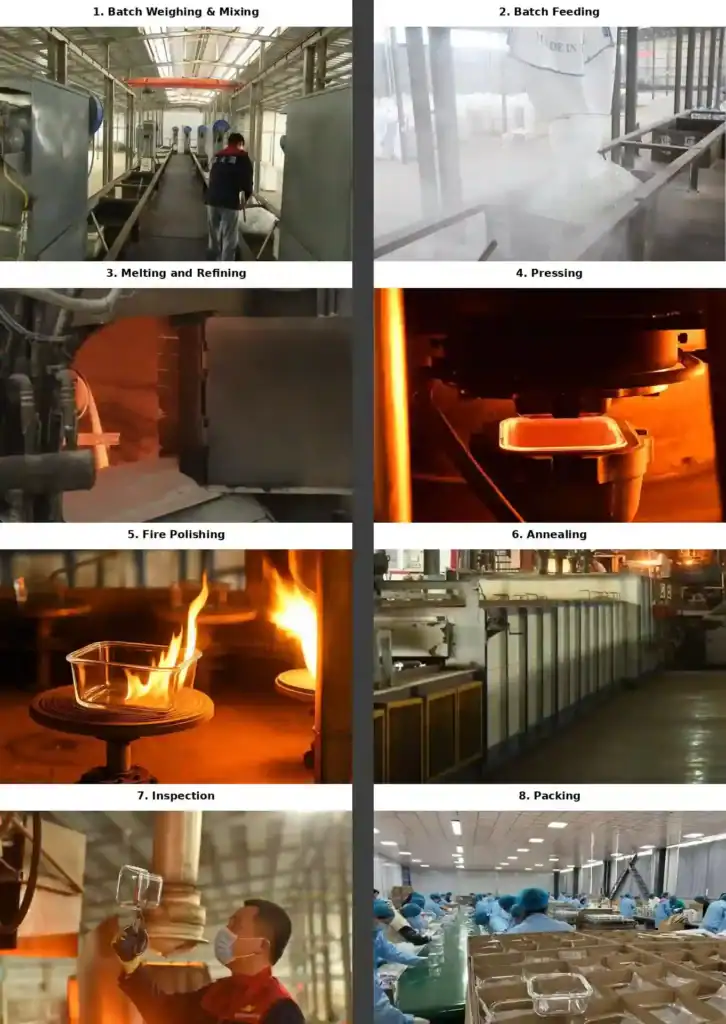

The manufacturing of glass food containers involves multiple steps—from raw material preparation, melting, and forming to polishing, annealing, and quality inspection—all designed to ensure safety, clarity, and durability. This end-to-end sequence is what defines the modern glass manufacturing process 1{#ref-1} that top-tier producers follow.

From silica sand to a finished container on the supermarket shelf, each step plays a critical role. This article walks you through the entire process of making glass food containers, the key factors affecting quality, and how the industry is evolving towards greener and more efficient production. Whether you’re sourcing from a food container manufacturer 2{#ref-2} overseas or evaluating a domestic glassware manufacturer 3{#ref-3}, understanding these steps helps you make informed decisions about your next glass container production partner.

Raw Materials Preparation — What Are Glass Containers Made Of?

At first glance, glass may seem like just sand, but the real recipe is both scientific and strategic.

Glass food containers are primarily made from silica sand, boric acid, and borax, with specific additives to enhance strength, clarity, and heat resistance.

To ensure product consistency and performance, our factory sources premium-grade borax from the U.S. and Turkey.

To produce borosilicate glass—the type commonly used in food containers—high-purity silica sand is used as the structural base. Boric acid and borax enhance heat and chemical resistance, making the containers suitable for ovens and microwaves. Additives like alumina and soda ash help lower the melting point and improve flow during forming. These raw material details are in line with typical container-glass formulations in industry reports. 4{#ref-4}

Raw Material Breakdown

| Material | Function | Common Ratio (%) |

|---|---|---|

| Silica Sand (SiO₂) | Structure and transparency | 70–75 |

| Boric Acid / Borax | Heat and chemical resistance | 10–15 |

| Soda Ash (Na₂CO₃) | Lowers melting point | 10 |

| Alumina / Lime | Adds strength and stability | 3–5 |

Even tiny impurities can affect color and clarity, so all materials must be cleaned, dried, and precisely mixed. I once visited a factory in Zibo where every batch was tightly controlled—you could literally see the difference in the final shine of the glass.

Melting Process — How Does Sand Become Glass?

Turning sand into glass is where chemistry meets engineering.

The raw mix is melted in a furnace above 1500 °C until it becomes uniform, bubble-free molten glass ready for shaping. This is consistent with standard container-glass production sequences. 5{#ref-5}

Inside the furnace, the mix transitions from solid grains to a glowing orange liquid. The key is maintaining even temperature and ensuring full homogenization. Any imbalance can result in bubbles, streaks, or structural weaknesses.

These melting conditions are foundational to any reliable glass container production process and must be controlled carefully to maintain quality.

Key Melting Steps

| Step | Purpose | Control Factor |

|---|---|---|

| Batch Loading | Feed raw materials evenly | Weight control system |

| Melting (>1500°C) | Turn solids into molten glass | Stable temperature |

| Homogenization | Mix molten glass uniformly | Stirring / air mixing |

| Bubble Removal | Eliminate trapped gases | Retention time |

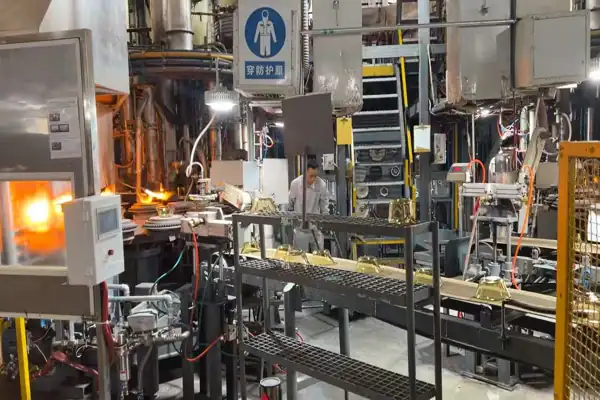

Modern plants use sensors to monitor furnace temperature, oxygen levels, and viscosity in real-time. The more stable the melting, the clearer and stronger the final product. That’s why the best food container manufacturers invest heavily in furnace technology.

Forming the Containers — How Is Molten Glass Shaped?

This is the moment when liquid glass becomes a usable container.

Glass containers are formed using press-forming or blow-forming methods, depending on shape, controlled by mold temperature and air pressure. Such forming methods align with industry standard practices. 6{#ref-6}

Molten glass is cut into measured gobs and dropped into molds. For bowls or lids, press-forming uses a plunger to shape the glass. For bottles and narrow shapes, blow-forming inflates the gob with air inside the mold.

Forming Method Comparison

| Method | Common Use | Key Controls |

|---|---|---|

| Press-forming | Bowls, plates, lids | Mold temperature, pressure |

| Blow-forming | Bottles, jars | Air pressure, timing |

| Combination | Complex shapes | Press & blow together |

Molds made from cast iron or steel define the final shape and texture. Both glass and mold temperatures must be precisely controlled—too cold, and cracks form; too hot, and the shape warps. I once helped a factory in Shandong adjust their mold cooling and saw the defect rate drop by 20%.

This stage is where the expertise of a seasoned glassware manufacturer truly shines, particularly in managing thermal stress and shape uniformity.

Surface Polishing — How Does Glass Get Its Shine?

Every gleaming container goes through fire.

Glass containers are polished using oxygen-rich fire to remove micro-defects and improve surface clarity.

During this step, the containers pass through a fire-polishing furnace. The intense flame slightly melts the surface layer, sealing micro-cracks and smoothing imperfections. This enhances clarity and boosts chemical durability.

Fire Polishing Parameters

| Parameter | Typical Range | Effect on Quality |

|---|---|---|

| Temperature | 700–900°C | Too low: dull; too high: warped |

| Flame Composition | Oxygen + fuel gas | Controls depth and clarity |

| Exposure Time | 2–5 seconds | Balance shine and strength |

Though short, this step makes a visible difference—consumers often notice the glossy clarity without knowing how it’s achieved. Fire-polishing also reinforces the appearance and surface hardness that buyers expect when asking: are glass food storage containers safe?

Annealing — Why Is Cooling So Important?

The strongest glass is not made by heat—but by cooling.

Annealing gradually cools containers in a controlled furnace to relieve stress and prevent breakage. This is a known key step in container glass manufacturing. 7{#ref-7}

Freshly formed glass contains internal tension. If cooled too fast, it can shatter later. In the annealing lehr, containers pass through different zones of decreasing temperature. This allows internal stresses to even out.

Annealing Temperature Curve

| Zone | Temperature | Function |

|---|---|---|

| Entry | 550–600°C | Equalize surface temperature |

| Middle | 450–500°C | Relieve internal stress |

| Exit | <100°C | Prepare for inspection |

A robust annealing process is what separates low-quality goods from containers designed to last—something every food container supplier must prioritize.

Quality Inspection — How Is Quality Ensured?

Not every container makes it to packaging.

Each glass container undergoes visual, dimensional, and automated inspections to ensure consistency and safety.

Quality Inspection Methods

| Test Type | Purpose | Equipment Used |

|---|---|---|

| Visual Inspection | Spot cosmetic defects | Light / camera system |

| Stress Testing | Detect internal tension | Polarimeter / stress gauge |

| Thickness Measurement | Ensure even wall strength | Ultrasonic sensors |

| Airtightness Test | Verify sealing capability | Pressure chamber |

Top-tier manufacturers also conduct chemical migration and food-contact tests to meet global standards. For example, industry players emphasise such compliance when sourcing “glass food containers made in USA” or with verified food-grade safety. 8{#ref-8}

Packaging and Delivery — How Is Glass Shipped Safely?

Glass is strong—but fragile during transport.

Glass containers are packed with custom inserts and shock-resistant materials to ensure safe shipping and meet customer packaging requirements.

Packaging Options

| Type | Use Case | Key Advantages |

|---|---|---|

| Single Box | Retail-ready | Attractive branding |

| Partition Carton | Bulk transport | Lower cost, easy stacking |

| Pallet + Shrink Wrap | Mass shipments | Fast and automated packing |

If you’re working with a global food container supplier 9{#ref-9}, ensuring logistics and labeling standards align with export regulations is critical.

Quality Control and Testing Methods — How Is Consistency Maintained?

Maintaining quality is an ongoing task.

Manufacturers use online sensors and offline labs to detect cracks, stress, and chemical migration to ensure compliance and durability. Detailed energy and material-flow modelling can map CO₂ emissions through the whole process. 10{#ref-10}

Common Tests and Categories

| Test Type | Focus Area | Method Used |

|---|---|---|

| Thermal Resistance | Heat shock & oven use | Temperature cycling |

| Chemical Durability | Acid/base resistance | Soak and wash tests |

| Migration Testing | Food safety compliance | Simulant extraction |

| Stress/Crack Detection | Structural safety | Polarized light / ultrasonic |

Whether you’re sourcing from a domestic factory or offshore manufacturer, consistent testing is the only way to ensure long-term performance.

Environmental Impact and Sustainability — Is Glass Really Eco-Friendly?

Glass’s beauty goes beyond its look.

Glass is endlessly recyclable, and modern plants reduce emissions, energy use, and waste for a greener future. Many European initiatives confirm this push. 11{#ref-11}

Sustainability Strategies

| Focus Area | Action Taken | Environmental Benefit |

|---|---|---|

| Recycling | Use of cullet | Reduces energy and raw material |

| Waste Management | Control gas, water, solids | Minimizes pollution |

| Lightweight Design | Optimize wall thickness | Saves on transport energy |

| Renewable Energy | Electric/hybrid furnaces | Lower carbon emissions |

As more brands seek sustainable packaging options, investing in eco-friendly “glass container production” is both a business and environmental win. According to one market report, lightweight glass container manufacturing is a growing trend across Asia-Pacific. 12{#ref-12}

Automation and Production Efficiency — How Are Modern Glass Plants Optimized?

Glass factories today are driven by automation.

Robots, sensors, and data systems increase precision, reduce defects, and boost production efficiency. Efficiency studies highlight process automation and data-analysis as key drivers. 13{#ref-13}

Key Automation Features

| System Component | Role | Outcome |

|---|---|---|

| Robotic Handling | Move hot containers safely | Fewer human errors |

| Online Data Collection | Monitor quality/temperature | Early defect detection |

| Predictive Maintenance | Prevent breakdowns | Less downtime |

| Line Layout Design | Optimize material flow | Faster cycle times |

These smart systems are becoming the norm among leading glassware manufacturers around the world. If you’re evaluating a partner, you’ll want to examine their automation and continuous-improvement programs.

Market Applications and Future Trends — Where Is Glass Headed?

Glass has been around for centuries, but it continues to evolve.

Global markets demand diverse sizes and designs, while future trends focus on lightweight, durable, and more sustainable packaging.

Market & Trend Summary

| Region | Popular Design | Emerging Trend |

|---|---|---|

| North America | Oven-safe, airtight sets | Smart lids & labeling |

| Europe | Clear minimalist jars | Recycled/lightweight glass |

| Asia-Pacific | Compact multi-use sets | Glass-polymer hybrid designs |

Whether you’re building your brand with glass food containers made in USA or exploring private-label opportunities abroad, partnering with the right food container manufacturer makes all the difference.

Conclusion

From silica sand to supermarket shelves, the journey of a glass food container is both complex and carefully controlled. Each stage—from melting and forming to inspection and shipping—defines final quality. With automation and sustainability leading innovation, glass remains one of the safest and most future-ready packaging materials in the world.

Understanding these glass manufacturing process steps not only improves product reliability but also helps brands choose the right food container manufacturer in a competitive market.

Footnotes

1. Overview of glass manufacturing steps and batch composition. ↩︎

2. Supplier profile: Slyprc custom glass food container manufacturer. ↩︎

3. Wikipedia summary of glass container forming methods (“blow & blow”, “press & blow”). ↩︎

4. Blog article on glass composition and raw materials in container glass. ↩︎

5. Comprehensive overview of glass melting and homogenization in container production. ↩︎

6. Research article on container glass forming technologies. ↩︎

7. Document describing annealing in container glass process. ↩︎

8. Article on inspection and food-contact compliance in glass containers. ↩︎

9. Blog on choosing glass packaging suppliers and manufacturing technology for containers. ↩︎

10. Academic modeling of energy, material flow and CO₂ in container glass manufacturing. ↩︎

11. Industry report on lightweight container glass manufacturing trend. ↩︎

12. Market outlook for lightweight glass containers in Asia-Pacific. ↩︎

13. Study on automation & productivity in glass container manufacturing. ↩︎