Finding a reliable glassware supplier can be challenging. A single weak link in your supply chain can cause shipping delays, quality issues, and brand damage. Choosing a trustworthy glass bowl manufacturer is no longer optional — it’s a competitive necessity.

To find the best glass bowl manufacturers in the USA, focus on certified suppliers with a proven record, quality assurance systems, and sustainable production practices. Look for partners that offer OEM/ODM services and comply with FDA, LFGB, and DGCCRF standards.

Having spent 15+ years in the glassware industry, I’ve seen the difference between products that simply look good and those that actually perform well. This guide will help you identify reliable American manufacturers, understand pricing logic, and choose suppliers that strengthen — not strain — your business.

What Defines the U.S. Glass Bowl Market Today?

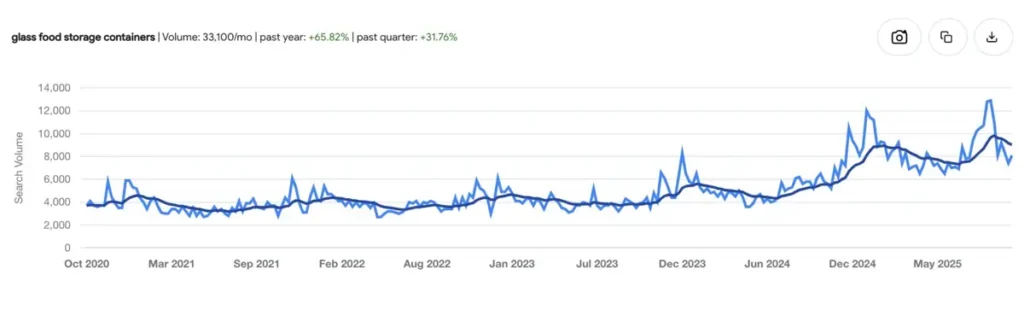

The U.S. glass bowl market is growing fast, driven by sustainability, durability, and consumer demand for American-made products. Buyers increasingly prioritize eco-friendly borosilicate glass 1{#ref-1} and transparent safety certifications.

The American glassware industry has undergone a major transformation. Once focused primarily on price competition, the market now rewards innovation, eco-conscious design, and verified safety.

Growth of the U.S. Glassware Industry

With more people cooking at home, durable and versatile glass bowls are in high demand. Multi-purpose bowl sets that move from oven to table to fridge are now a standard expectation. At PYGLASS, we’ve seen rising orders for borosilicate sets that withstand both heat and cold — a reflection of the “fewer but better” trend.

Why American-Made Glass Bowls Stand Out

The “Made in USA” label carries weight. Domestic manufacturers often offer shorter lead times and stronger communication. That responsiveness helps purchasing managers meet strict retail deadlines — something that offshore factories often struggle with.

How Consumer Trends Are Shaping the Market

Modern consumers are educated and cautious. They prefer BPA-free, non-toxic glass 2{#ref-2} over plastic. They also want traceability — knowing their purchase supports sustainable, transparent production. This mindset aligns perfectly with the PYGLASS mission: Safer · Healthier · Greener.

| Trend | Market Effect | Buyer Takeaway |

|---|---|---|

| Sustainability | 25% YoY growth in eco-glass sales | Choose borosilicate over soda-lime |

| Local manufacturing | Shorter lead times, higher trust | Highlight “Made in USA” stories |

| Durability focus | Decline in plastic storage demand | Market reusable, long-life glass sets |

Why Choosing the Right Glass Bowl Manufacturer Matters

Your choice of manufacturer directly affects product quality, brand reputation, and profit margins. The right partner delivers safe, consistent products on time — the wrong one costs you customers and credibility.

A glass bowl supplier isn’t just a vendor — they’re a long-term business partner. Their reliability becomes your reliability.

In my 15 years in this business, I’ve learned that the sticker price is just one part of the equation. I call it the “total cost of ownership.” A cheaper supplier might save you 5% upfront, but if their breakage rate is higher or their lids don’t seal, you’ll pay for it ten times over in returns and reputation damage. A reliable partner is an investment, not an expense.

Quality, Durability, and Safety Standards

A strong manufacturer starts with high-quality raw materials like borosilicate glass, known for its resistance to thermal shock 3{#ref-3}. Ensure the supplier meets key food safety standards such as FDA, LFGB, and DGCCRF 4{#ref-4}.

| Certification | Region | Significance |

|---|---|---|

| FDA | USA | Ensures glass is safe for direct food contact |

| LFGB | EU (Germany) | Guarantees non-toxic and safe materials |

| DGCCRF | France | Confirms compliance with EU food contact laws |

Design Innovation and Customization Options

Look for a custom glass bowl manufacturer 5{#ref-5} that supports OEM/ODM development. Can they help you design stackable sets, leak-proof lids, or embossed branding? These features differentiate your product line.

Sustainability as a Core Value

Consumers now expect eco-friendly production. The best manufacturers recycle waste glass, use energy-efficient furnaces, and design minimal packaging. Working with such partners strengthens both your ESG story and your sales appeal.

Top Glass Bowl Manufacturers in the USA (2025 Edition)

Leading American glass bowl manufacturers include Libbey, Anchor Hocking, and specialized OEM suppliers offering custom production and wholesale pricing. Choose based on MOQ, design flexibility, and certification transparency.

Different buyers have different needs. A small retailer may want low MOQs and fast turnaround; a national distributor may prioritize capacity, brand reputation, and compliance documentation.

Leading Wholesale Glass Bowl Suppliers

Wholesale suppliers offer glass bowls wholesale with shorter lead times and ready stock. These partners often carry pre-certified designs that reduce compliance overhead.

Notable Brands Offering Custom Glass Bowl Production

American icons like Libbey 6{#ref-6} and Anchor Hocking 7{#ref-7} have mastered large-scale glassware production. Meanwhile, specialized importers and manufacturers like PYGLASS deliver custom, OEM-level flexibility with international certifications — ideal for private-label lines.

| Manufacturer | Specialty | Ideal Buyer |

|---|---|---|

| Libbey | Premium consumer glassware | Retail brands |

| Anchor Hocking | Heat-resistant glass bowls | Home goods retailers |

| PYGLASS | OEM/ODM, borosilicate sets | Distributors & importers |

How to Identify Reliable U.S. Manufacturers

Check their audits (ISO9001, BSCI) 8{#ref-8}, client portfolio, and response time. Transparency and clear documentation are the best indicators of a long-term partner.

Comparing Glass Bowl Set Prices and Value

The best deal isn’t always the lowest price. Evaluate total value — including quality, durability, packaging, warranty, and after-sales support.

A high-quality glass bowl set costs more upfront but saves you money later through fewer returns and stronger brand loyalty.

What Affects Glass Bowl Pricing?

- Material Type: Borosilicate > Soda-lime for strength and heat resistance.

- Thickness: Heavy-gauge glass is safer but uses more raw material.

- Design Complexity: Embossing, colors, and lids increase costs.

- Volume: Bulk orders reduce per-unit cost significantly.

- Certifications: Testing and compliance add short-term cost but ensure longevity.

| Cost Driver | Effect on Price | Buyer Tip |

|---|---|---|

| Borosilicate Glass | +15–20% | Worth it for heat durability |

| Thicker Walls | +10% | Reduce breakage rate |

| Custom Embossing | +5% | Adds brand value |

| Bulk Orders | -15% | Use MOQ leverage |

| Eco-Packaging | +3% | Boosts brand story |

Wholesale vs. Retail Pricing

Retail pricing includes distribution, marketing, and margins. As a B2B buyer, focus on wholesale glass bowls that provide sustainable pricing across seasons.

How to Get the Best Bulk Deals

- Commit to steady volume for discounts.

- Streamline designs to optimize mold and packing costs.

- Negotiate value terms — warranty, defect rate, or lead time instead of just price.

- Build a partnership — reliable buyers always get priority pricing.

Where to Buy Glass Bowls Wholesale in the USA

You can source bulk glass bowls through major B2B marketplaces 9{#ref-9}, trade fairs, or directly from certified wholesale glassware suppliers in the USA.

Top B2B Marketplaces for Bulk Glassware

- MFG.com: An online marketplace specifically for sourcing custom manufacturing services from U.S.-based fabricators.

- Global Sources: Curated manufacturers with verified audits.

- ThomasNet: Lists U.S. suppliers with detailed certifications and contact info.

Trusted Online Platforms and Direct Channels

For repeat orders, establish direct communication via brand websites. Custom glass bowl manufacturer networks often provide private catalogs, sample programs, and volume-based pricing.

Negotiation Tips for Wholesale Buyers

- Know your target cost and competitor benchmarks.

- Request written warranties and replacement terms.

- Ask for packaging photos or drop-test videos before confirming PO.

- Always clarify MOQ, payment terms, and lead times.

| Channel | Best For | Key Advantage |

|---|---|---|

| Alibaba | International buyers | Broad selection, competitive prices |

| Global Sources | Quality-focused buyers | Verified supplier network |

| ThomasNet | U.S. domestic buyers | Local transparency, faster delivery |

| PYGLASS Direct | OEM/ODM brands | Customization, compliance support |

Key Factors to Consider Before Bulk Purchasing

Before placing large orders, confirm specifications, MOQ, lead time, and packaging standards. Always approve a production-equivalent sample to avoid surprises.

Material Quality and Sample Testing

Order a pre-production sample 10{#ref-10} that uses the same materials and molds as final production. Test it — heat it, freeze it, dishwash it. Don’t approve the bulk order until the sample meets your standards.

MOQ and Lead Time

- MOQ: Match with your forecast to prevent overstock.

- Lead Time: Add a 2-week buffer for logistics delays.

| Supplier | MOQ (Units) | Lead Time (Days) | Per-Unit Cost |

|---|---|---|---|

| Supplier A | 3,000 | 45 | $5.50 |

| Supplier B | 2,000 | 60 | $5.75 |

| Supplier C | 5,000 | 40 | $5.20 |

Packaging, Branding, and Private Label

Ask about private label options — embossed logos, printed lids, and branded packaging. Premium packaging reduces breakage and enhances shelf appeal, a win for both protection and marketing.

Why “Made in USA” Still Matters

“Made in USA” symbolizes quality, safety, and trust. It reflects stricter regulations, ethical manufacturing, and local job creation — values that resonate with modern consumers.

Even though PYGLASS operates in China, our values align with these same principles. We meet the standards that define “Made in USA”: ISO9001, BSCI, FDA, LFGB, DGCCRF compliance, and audits by global retailers like Walmart and Costco.

The label itself is less important than the values behind it — quality, safety, and transparency. Those are the universal hallmarks of a great manufacturer.

| Advantage | Meaning | Buyer Impact |

|---|---|---|

| Quality Control | Strict U.S. standards | Reliable performance |

| Local Jobs | Domestic production | Ethical brand appeal |

| Lower Emissions | Shorter transport | Sustainability boost |

Final Thoughts: Partnering for a Safer, Healthier, Greener Future

Choosing the right glass bowl supplier isn’t just about cost — it’s about building reliability, reducing waste, and protecting your brand.

At PYGLASS, we manufacture high-borosilicate glass bowls, containers, and bakeware that meet global safety standards (FDA, LFGB, DGCCRF). With ISO9001 and BSCI certification, we provide OEM/ODM solutions that balance design, safety, and sustainability.

Contact PYGLASS today to explore bulk pricing, private label options, and product samples that fit your brand’s “Safer · Healthier · Greener” promise.

—

Footnotes

1. Explore the properties of borosilicate glass, known for its superior thermal stability and eco-friendly composition in cookware. ↩︎

2. Learn from the Mayo Clinic about the health risks associated with BPA and the benefits of using BPA-free products. ↩︎

3. A scientific overview of thermal shock resistance, explaining why certain materials can withstand rapid temperature changes without cracking. ↩︎

4. Understand the EU’s stringent food contact regulations, which ensure consumer safety for imported and domestic kitchenware products. ↩︎

5. Discover custom glassware solutions from Slyprc, specializing in high-borosilicate glass products for OEM/ODM business clients. ↩︎

6. Visit the official retail site of Libbey, a prominent American glassware manufacturer offering a wide range of products. ↩︎

7. Explore Anchor Hocking’s collection of American-made bakeware and food storage, known for its long-standing reputation for durability. ↩︎

8. Learn about the amfori BSCI audit, a leading social compliance system that promotes ethical and responsible supply chains. ↩︎

9. Thomasnet is a leading B2B platform for sourcing industrial products and connecting with North American manufacturers and suppliers. ↩︎

10. Understand why pre-production samples are a crucial quality control step to prevent costly errors before mass production begins. ↩︎