Are you frustrated with high sourcing costs from middlemen? These extra costs cut into your margins and make your products uncompetitive in a tough market. Buying direct from a verified factory is the solution. I will show you how to do it right.

The best place to buy airtight containers direct is from verified manufacturers in established production hubs, like Zibo, China. This approach cuts costs, improves communication, and gives you direct control over quality, customization, and compliance.

As a purchasing manager, you know sourcing is complex. You are always balancing price, quality, and supplier reliability 1{#ref-1}. I have been in the glass manufacturing industry for over 15 years. I have seen many buyers make the same costly mistakes. Before you source your next container line, we should cover the basics. This will ensure you get the best total value, not just the lowest price.

What Are Airtight Containers for Food Storage?

Food spoils quickly in the wrong container. This wastes money for consumers and creates customer complaints for you. Airtight containers are designed to solve this specific problem.

Airtight containers for food storage are vessels designed with a special sealing mechanism. This mechanism is usually a silicone gasket and locking clips. This design stops air and moisture from entering. This keeps food fresh, prevents spills, and blocks odors.

When I first started in this industry 15 years ago, “storage” just meant a box with a simple lid. But retailers, maybe like you, kept bringing me complaints from their customers. Lids popped off in bags. Sauces leaked. We quickly learned that the seal was the most critical part. A container that does not seal properly is just a box.

The Anatomy of an Airtight Seal

What makes a container truly “airtight”? It is not just one part. It is a system of parts working together. If one part fails, the whole container fails.

- The Gasket: This is the soft ring, usually made of silicone. It sits in the lid. It must be flexible to create a tight seal. It must also be durable. It cannot stretch or tear after a few uses. We use only food-grade, high-quality silicone 2{#ref-2}.

- The Locking Mechanism: These are the clips or snaps on the lid. Most of our lids use a four-point locking system. This system applies even pressure to the gasket. This even pressure is key to stopping leaks.

- The Base: The container base must have a smooth, flat rim. If the rim has any dips or bumps, the gasket cannot seal against it. This is a common quality control failure in cheap factories.

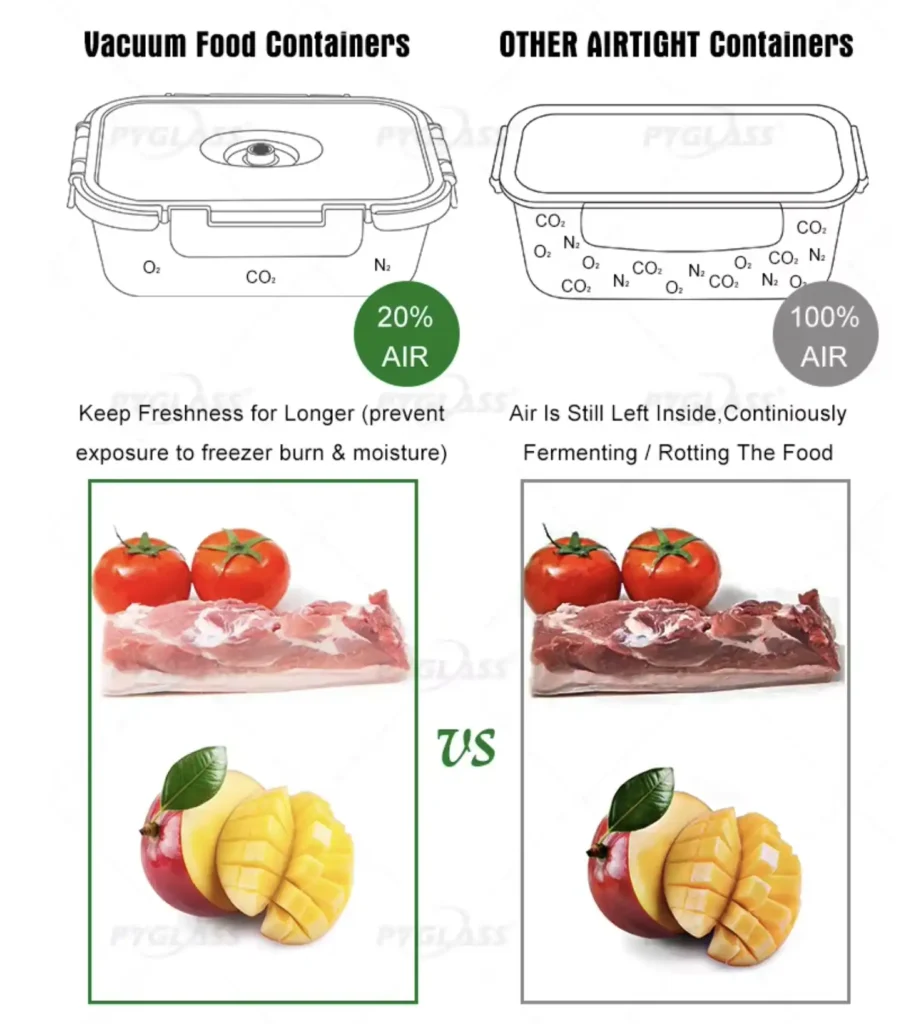

This system creates a standard airtight seal. But we also take this one step further with vacuum seal technology. This system uses a special lid with a one-way air valve. A vacuum pump (either manual or electric) attaches to this valve to remove all the air from the container. This is not just airtight; it is vacuum-sealed, which can keep food fresh up to five times longer 3{#ref-3}. This is a key innovation we offer.

Material Matters: Glass vs. Plastic

As a purchasing manager, you are sourcing both. But the trend is moving strongly toward glass.

- Glass: We specialize in high borosilicate glass. This is the key material. It can handle extreme temperature changes. Your customers can take it from the freezer directly to the oven. It does not stain, even with tomato sauce. It does not absorb smells. It is also infinitely recyclable. This is what we focus on at PYGLASS.

- Plastic: Plastic containers are cheaper and lighter. But they have many problems. They stain. They warp in the microwave. They absorb odors. Consumers are also very worried about chemicals like BPA 4{#ref-4} leaching into their food.

Table: Comparing Container Materials

| Feature | High Borosilicate Glass (PYGLASS) | Regular Glass (Soda-Lime) | Plastic (PP) |

|---|---|---|---|

| Thermal Shock | Excellent (Oven/Freezer Safe) | Poor (Can shatter) | Good (Microwave safe) |

| Stain/Odor | Does not stain or absorb odors | Does not stain or absorb odors | Stains and absorbs odors |

| Health & Safety | 100% non-porous, no chemicals | 100% non-porous, no chemicals | Risk of BPA/leaching |

| Durability | Very durable, can break | Breaks easily | Does not break, but warps |

| Eco-Friendly | 100% Recyclable (Greener) | Recyclable | Hard to recycle, pollutes |

Airtight is also not the same as “leak-proof.” Airtight stops air. Leak-proof stops liquid. A great container must be both. We test this on every production run. I remember one client who sourced cheap containers that were “airtight.” But they leaked soup in a customer’s bag. It was a disaster for their brand. We had to develop a new, thicker gasket just for them. This focus on small details is what separates a real supplier from a simple factory.

Why Airtight Containers for Food Storage Are So Popular?

Consumers are tired of food waste and messy kitchens. Single-use plastic is also a huge environmental concern for them. Airtight containers offer a perfect, reusable solution.

Airtight containers are popular because they solve major consumer problems. They extend food freshness, which saves money. They help organize kitchens. They are portable for lunches, preventing leaks. And glass options offer a safe, eco-friendly alternative to plastic.

The market for these products is not just growing; it is exploding. As a category manager, you see this in your sales data. But why? I see three main drivers from my position as a manufacturer. These are the trends your customers care about.

The Economic Driver: Reducing Food Waste

Food is expensive. When consumers throw away spoiled fruit or leftovers 5{#ref-5}, they are throwing away money. An airtight container keeps food fresh longer. A high-quality container can keep lettuce crisp for a week instead of two days. It keeps dry goods like cereal and pasta safe from moisture. I talk to retailers constantly. They tell me their customers want value. A $5 container that saves $50 in groceries over its life is an easy sale. Your products need to deliver on this promise of freshness.

The Health and Safety Movement

This is a huge trend. You know this from your compliance needs, like FDA and LFGB 6{#ref-6}. Consumers are thinking more about what touches their food.

- Plastic Worries: People are moving away from plastic. They read articles about microplastics and chemicals like BPA. They do not want to microwave their food in plastic. They worry about chemicals leaching into their family’s meals.

- Glass as the Safe Solution: Borosilicate glass is non-porous and pure. It does not react with food at all. It is the “Safer, Healthier” part of our PYGLASS mission. When I founded PYGLASS, this was my main goal. I saw too many factories in the industry cutting corners on material safety. We decided to build our brand on safety.

The Sustainability Trend

This is not a small trend. It is a permanent shift in consumer values. Your company likely has green initiatives. Consumers demand it. Retailers like you must respond.

- Reducing Single-Use Plastic: Consumers want to stop using plastic bags and plastic wrap. Reusable glass containers are the perfect alternative.

- Recyclability: Glass is 100% recyclable. It can be melted down and remade into new glass forever. It fits the “Greener” part of our slogan. Sourcing glass products helps you meet your company’s sustainability goals.

These three drivers—saving money, protecting health, and helping the planet—are why this category is so strong.

The Critical Factors in Sourcing Airtight Containers for Food Storage in Bulk?

Choosing the wrong supplier can be a disaster for your business. You get bad quality, late shipments, and even legal risks. You must check these critical factors first.

**When sourcing in bulk, focus on five factors: *Material Quality* (e.g., high borosilicate glass), Seal Effectiveness (leak-proof), Compliance (FDA, LFGB), Production Capacity (can they meet your volume?), and Logistics (packaging to prevent breakage).**

As a purchasing manager, you are juggling many risks. I understand this. I work with PMs like you every single day. One of your biggest pain points is quality. A bad product leads to high return rates. Another pain point is tight lead times. A late shipment can make you miss a whole sales season.

I remember one new customer, let’s call him David. He was a PM for a European retailer. He switched to a cheaper supplier to save 5% on cost. But the new factory was late. He missed the back-to-school promotional window. He saved 5% on the order but lost 20% in yearly sales for that category.

Let’s break down the factors so this does not happen to you.

Factor 1: Quality and Compliance (Your Biggest Risk)

This is non-negotiable. You must get proof.

- Test Reports: Ask for them. A real factory will have them ready. You need FDA (for the US), LFGB (for Germany/EU), and DGCCRF (for France). If they cannot provide these, walk away.

- Factory Audits: You need to know the factory is run professionally. Ask for their ISO9001 (quality management) and BSCI (social compliance 7{#ref-7}) reports. We pass these audits for clients like Walmart and Costco. This removes your legal and reputational risks.

Factor 2: The Lid and Seal (The Point of Failure)

I said this before, but it is important. This is where 90% of problems happen.

- Lid Material: The lid should be sturdy PP (polypropylene).

- Gasket: The seal must be food-grade silicone, not cheap TPE.

- Testing: Ask the supplier how they test for leaks. We have a machine that opens and closes the locks 10,000 times. We also do 24-hour water-fill tests.

Factor 3: Packaging and Logistics (The Breakage Problem)

One of your key pain points is fragility. Glass breaks. It is a fact. But how it is packed makes all the difference. Breakage in transport is a direct cost to you.

We use strong, 5-ply outer cartons. We use reinforced inner dividers. For some high-value sets, we use molded pulp inserts. We perform drop tests from 1 meter. You should ask your supplier for their drop test standards. This protects your supply chain costs.

Table: Key Sourcing Questions for Suppliers

| Factor | Key Question to Ask | What a Good Answer Looks Like | Red Flag (Bad Answer) |

|---|---|---|---|

| Compliance | “Can you send your BSCI and LFGB reports?” | “Yes, here is our 2025 BSCI report.” | “We will get those…””Our materials pass.” |

| Material | “Is this high borosilicate glass?” | “Yes, our glass contains >8% boron.” | “It is strong glass.””It is oven-safe.” |

| Lid Seal | “What is your leak-testing process?” | “We do a 10,000-cycle lock test and 24-hour water test.” | “We check the lids.” |

| Packaging | “What is your standard drop test?” | “We pass a 1-meter drop test on 6 sides.” | “We use strong cartons.” |

Where to Buy: Navigating the Airtight Containers for Food Storage Sourcing Channels?

You need to find a supplier, but where do you even look? The options can be overwhelming, from online platforms to trade shows to agents. Let’s compare the main channels.

You can source through online B2B platforms, trading companies (agents), or directly from a factory (like PYGLASS). Platforms offer wide choice but high risk. Agents add cost. Direct sourcing gives you the best price, control, and communication.

You probably use all these channels. As an experienced PM, you know their pros and cons. But I want to share my perspective as a factory owner.

Channel 1: Online B2B Platforms

These sites are your first search, like a search engine.

- Pros: You get a huge selection. It is easy to find thousands of suppliers and get quick quotes.

- Cons: It is very hard to verify who you are talking to. Are they a real factory? Or are they a 3-person trading company in a small office? Many “verified suppliers” are just agents. You must do deep vetting. It is a lot of work.

Channel 2: Trading Companies / Agents

Agents can be helpful 8{#ref-8}, especially for smaller orders.

- Pros: They can find products for you and consolidate shipments. They often speak your language well.

- Cons: They add a 10% to 20% margin to the factory price. You are paying more. You also have no direct contact with the factory. If there is a quality problem, the communication is slow. You lose control over the process.

Channel 3: Trade Shows

This is a great way to meet suppliers.

- Pros: You can meet the team face-to-face. You can touch and feel the product quality. This is how I built many of my best long-term partnerships.

- Cons: It is very expensive and time-consuming. You have to travel internationally to attend. And you only see them once or twice a year.

Channel 4: The Best Option – Direct to Factory

This is our model at PYGLASS. We are the factory.

- Pros:

- Best Cost: There is no middleman. You get the factory-direct price.

- Direct Communication: You talk directly to our engineers and project managers.

- Customization: We can develop OEM/ODM products just for you.

- Transparency: You can audit our factory. In fact, we encourage it. Walmart and Costco have audited us.

- Cons: This option usually requires a higher MOQ (Minimum Order Quantity). But for a professional purchasing manager like you, your volumes usually meet this requirement.

I started PYGLASS because I was the factory making products for agents. I saw the disconnect. The buyer’s needs got lost in translation. By working directly with you, we solve problems faster and build better products.

PYGLASS: Your Premier Partner for Airtight Food Storage Solutions?

You need a reliable, certified, and innovative factory. But finding one you can trust is the hardest part of your job. PYGLASS was built to be that partner.

Yes, PYGLASS is a premier partner. We are a direct manufacturer with a 200,000㎡ base in Zibo, China. We offer high borosilicate glass, full compliance (FDA, LFGB, BSCI), and 15+ years of industry experience. We provide solutions, not just products.

I want to be direct with you. You have hundreds of choices. Here is why partners who care about quality and safety choose us.

We Are the Manufacturer, Not a Trader

I founded this company on the factory floor. We are not a sourcing agent. Our 200,000㎡ manufacturing base is real. You can visit it. This scale means we can handle your volume. It also means you get factory-direct pricing, which protects your margins.

We Solve Your Compliance Problems

One of your biggest pain points is compliance risk. We eliminate it.

- Product Safety: We have the test reports for FDA, LFGB, and DGCCRF. They are ready for you.

- Factory Audits: We have passed BSCI, ISO9001, and major retailer audits like Walmart and Costco.

When you partner with us, your legal and compliance team can relax.

We Solve Your Quality and Logistics Problems

You have pain points around quality (bad lids) and logistics (breakage).

- Quality: Our specialty is high borosilicate glass. This is the core of our “Safer, Healthier, Greener” mission. It is a premium material.

- Logistics: We ship to North America, Europe, and Latin America every day. We serve over 50 major brands. We know exactly how to pack glass for international shipping to solve your “high fragility” cost.

We Solve Your Innovation Problem

You mentioned that suppliers often lack design innovation. You need “Engineering & Design Support.” We have an in-house R&D team. We do not just copy. We invent. We work on new stackable designs, better space-saving seals, and new technology like our vacuum-seal containers. We can be your OEM/ODM partner to build products nobody else has.

The Procurement Process: A Step-by-Step B2B Workflow?

You found a supplier, but the production process is unclear. This lack of clarity leads to mistakes, anxiety, and delays. A clear, professional workflow is essential.

A typical B2B workflow is: 1. Inquiry (you send your specs). 2. Quotation & Samples (you review cost and quality). 3. Order Confirmation (PO and deposit). 4. Mass Production & QC. 5. Logistics & Final Payment. 6. After-Sales Support.

You need “clear timelines and progress updates.” I designed our process specifically for professional managers like you. We assign a dedicated project manager to your account. This person is your single point of contact. Here is how we work together.

Step 1: Inquiry and Design (Your Vision)

You send us your Request for Proposal (RFP) or RFQ. You must include your specs, quantity, customization needs, and packaging art. If this is an ODM (Original Design) project, our engineers will schedule a call with you to discuss the design.

Step 2: Sampling and Quotation (The Proof)

We provide a detailed quote, usually FOB or CIF. At the same time, we prepare pre-production samples. You must approve this sample before we do anything else. This sample is your quality guarantee.

Step 3: Mass Production (Our Work)

Once you approve the sample and send the PO, we start. This is where our 200,000㎡ base matters. We can handle large volumes. We manage the raw materials and production schedule. This is how we work to hit your “tight lead times.”

Step 4: Quality Control (Your Peace of Mind)

We do not just check at the end. We have in-line QC during production. We also do a final AQL (Acceptable Quality Limit) 9{#ref-9} inspection. We welcome your third-party QC team (like SGS, Intertek, or QIMA) to come and inspect before shipment. We are 100% transparent.

Table: Our Project Management Milestones

| Phase | Action | Key Document | Who is Responsible |

|---|---|---|---|

| 1. Inquiry | Define product specs | Your RFQ / Tech Pack | You (Jacky) |

| 2. Sampling | Approve sample & price | Our Quotation / Sample | You & PYGLASS |

| 3. Order | Send PO and Deposit | Your Purchase Order | You (Jacky) |

| 4. Production | Produce & In-Line QC | Production Schedule | PYGLASS |

| 5. Final QC | Final Inspection | QC Report (Yours or ours) | You & PYGLASS |

| 6. Shipping | Ship goods | Bill of Lading (B/L) | PYGLASS |

This clear process ensures there are no surprises. You always know the status of your order.

Why Choose PYGLASS Airtight Containers?

You have many supplier choices in China and Vietnam. But choosing based on the lowest price alone is very risky. We offer a total value that goes far beyond price.

**Choose PYGLASS for three reasons: *Safety* (high borosilicate glass, 100% FDA/LFGB compliant), Reliability (15+ years experience, BSCI/ISO certified factory), and Innovation (in-house R&D for better sealing, stacking, and vacuum technology).**

Our slogan is “Safer · Healthier · Greener.” This is not just marketing. This is our production philosophy. It directly addresses your biggest sourcing needs.

Safer: Our Material Commitment

Our containers are made from high borosilicate glass. This is not regular, cheap soda-lime glass. This material can go from the freezer (-20°C) directly to a hot oven (400°C). It will not shatter from thermal shock 10{#ref-10}. This is a critical safety feature for your customers. It is also more durable against chips and cracks.

Healthier: Our Compliance Guarantee

Our products are healthier because they are pure. The glass is non-porous. It will not absorb stains, smells, or chemicals from food. This is a major problem with plastic. We guarantee that all our products pass FDA (for North America) and the strict LFGB (for Europe) tests. This removes your compliance and legal risks.

Greener: Our Environmental Responsibility

Glass is a natural material. It is infinitely recyclable. Your customers are demanding sustainable, plastic-free options. This is a key selling point for your retail brand. Sourcing from us helps you tell a good environmental story. Furthermore, our factory is BSCI audited. This (Business Social Compliance Initiative) means we treat our workers fairly and ethically. This protects your brand’s reputation from supply chain problems.

Your Flexible Partner

Finally, you need “Flexible Cooperation.” We provide this.

- OEM/ODM: We can create custom molds and designs just for you.

- Branded Packaging: We can design and produce your retail-ready color boxes.

- Flexible MOQs: We are a large factory, but we aim for long-term partners. We can discuss flexible MOQs to help you launch new products.

Meet the PYGLASS Top 6: Our Premier Airtight Storage Solutions?

You need innovative products that sell well. Basic containers are everywhere. Our top products solve specific consumer problems and give you a competitive edge.

Our top solutions include classic borosilicate containers, advanced vacuum-seal sets (manual and electric), an elegant glass-on-glass lid option, and high-performance freshness-focused sets. These products offer superior freshness, innovative features, and a 100% plastic-free food contact path.

As a category manager, you need to build a complete range. We can help you do that. Here are our 6 flagship products that show our R&D capabilities.

1. The Classic: Our Best Airtight Glass Containers

This is our workhorse line. It is the foundation of any kitchenware program.

- Base: High borosilicate glass.

- Lid: A 4-lock PP lid with a removable silicone seal.

- Features: It is 100% leak-proof, stackable for easy storage, and nestable to save shipping costs. This is the set every retailer needs.

- Link:

https://slyprc.com/product/best-airtight-glass-containers/

2. The Purist: Glass Containers with Glass Lids (9-Piece Set)

This product is our answer to the “100% plastic-free” demand.

- Base: High borosilicate glass.

- Lid: A heavy, durable glass lid.

- Features: The food only touches glass. A silicone seal is fitted to the lid to make it airtight. This is a beautiful, sustainable, high-end item for eco-conscious consumers.

https://slyprc.com/product/glass-food-storage-containers-glass-lids-9-piece-set/

3. The Innovator: Vacuum Seal Containers with Pump

This is our core vacuum-seal technology line, featuring the manual pump.

- Base: High borosilicate glass.

- Lid: A special lid with a one-way air valve.

- Features: This line is built around our reliable manual hand pump. The user pumps the air out, keeping food fresh 3-5 times longer than normal. This is a high-value item with great margins.

-

https://slyprc.com/product/vacuum-seal-containers-with-pump/

Components of Vacuum Seal Containers with Pump Let’s take a look at these meticulously designed components. Each part of the vacuum seal container plays a vital role. The hand pump, gasket, air valve, buckle, and borosilicate glass storage container all work together to keep your food as fresh as possible. This is the power of vacuum seal containers with a pump, extending the freshness of your food and making every bite as fresh as the first.

4. The Value Set: Vacuum Food Containers (10-Set Manual Pump)

This is the all-in-one set for consumers ready to adopt vacuum storage.

- Base: High borosilicate glass.

- Lid: One-way air valve lids.

- Features: This is a retail-ready 10-piece set built on our manual pump technology. It offers a complete storage solution for families and is perfect for a “starter kit” promotion.

-

https://slyprc.com/product/vacuum-seal-containers-pump-10-set-wholesale/

5. The Freshness Expert: Best Vacuum Containers for Freshness

This line is focused purely on performance and is a bestseller.

- Base: High borosilicate glass.

- Lid: One-way air valve lids.

- Features: These containers are optimized and tested for maximum freshness retention. They use the same reliable manual pump system and are perfect for high-value foods like coffee beans, nuts, and delicate herbs where spoilage is not an option.

https://slyprc.com/product/vacuum-seal-containers-pump-best-vacuum-containers-freshness/

6. The Tech Solution: Electric Vacuum Seal Glass Containers

This is the premium, effortless version of our vacuum line.

- Base: High borosilicate glass.

- Lid: Advanced valve lid.

- Features: It uses an automatic, rechargeable electric pump. The user just presses a button. This is perfect for high-end kitchenware brands and e-commerce. It shows your customers you are bringing them the latest technology.

- https://slyprc.com/product/vacuum-food-storage-containers-electric-pump/

These products show that we are thinking about the future. We can help you build an innovative and profitable category.

Conclusion

Sourcing airtight containers direct from the factory is the best way to get value, quality, and innovation. You must look past the simple unit price. You must focus on material safety, full compliance (FDA/LFGB), and a supplier’s logistics and R&D. A true partner, like PYGLASS, will help you solve your biggest pain points. We are not just a supplier; we are an extension of your team, dedicated to making your category successful.

Footnotes

1. Guide to assessing and vetting supplier reliability. ↩︎

2. FDA guidelines on food-grade silicone for contact materials. ↩︎

3. How vacuum sealing extends food preservation. ↩︎

4. Information on BPA and its potential health effects. ↩︎

5. EPA guide on how consumers can reduce food waste. ↩︎

6. Comparison of FDA and LFGB food contact material regulations. ↩︎

7. Overview of the BSCI for social compliance in supply chains. ↩︎

8. Comparing the pros and cons of using sourcing agents. ↩︎

9. Explanation of AQL standards in manufacturing quality control. ↩︎

10. The science behind borosilicate glass and thermal shock resistance. ↩︎