Are you struggling to find a reliable source for wholesale glass food containers? You know demand is booming, but supplier choices feel endless and risky. One wrong move can mean quality problems, missed shipments, and lost trust from your customers.

The best places to buy wholesale glass food containers are directly from professional glassware manufacturers, through reliable distributors, or via verified B2B marketplaces. Each channel fits a different need in cost, customization, and delivery delivery.

I’ve spent over 15 years in the glassware industry, and I’ve seen how buyers wrestle with sourcing decisions. Picking the right channel isn’t just a task—it shapes your supply chain, pricing, and reputation. Let me show you how to navigate this market with confidence and build long-term sourcing success.

How Can You Understand the B2B Glass Food Storage Containers Market?

You can’t buy smart if you don’t understand the market. Many buyers jump into negotiations without knowing where the demand comes from, which countries lead production, or what compliance standards matter most.

To succeed in the wholesale glass container market, you must understand global trends, main export regions, and which industries are driving demand.

When I entered this field, glass containers were seen as a niche category. Now, they’re the face of eco-friendly food packaging. Regulations against single-use plastics 1{#ref-1} and rising consumer health awareness 2{#ref-2} have created an enormous shift toward glass. The market for reusable containers is growing globally, with North America and Europe driving most of the import demand. Asia—especially China, India, and Vietnam—remains the core production hub thanks to established glassmaking infrastructure and competitive costs.

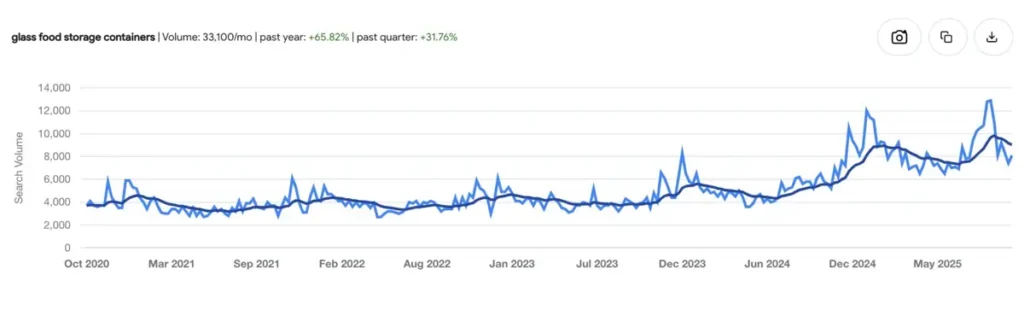

Global Market Overview

The global glass food storage container market 3{#ref-3} is valued at over USD 6 billion and continues to grow by more than 6% annually. Buyers are diversifying their sourcing bases to reduce risk from shipping disruptions and tariffs 4{#ref-4}.

| Region | Top Exporters | Main Importers | Growth Rate (2024–2029) |

|---|---|---|---|

| Asia | China, India, Vietnam | USA, Canada, Germany | 6.2% |

| Europe | France, Italy | UK, Netherlands | 4.5% |

| Americas | USA, Mexico | Canada, Brazil | 3.8% |

For a B2B buyer, knowing these numbers is more than trivia—it’s risk management. I’ve seen clients who source only from one country face costly delays when logistics break down. A good sourcing plan should balance cost with diversification.

Major Industries Using Glass Containers

Glass containers serve many industries—food processing, retail, hospitality, and meal-prep delivery. Each sector values glass for different reasons: it’s durable, non-toxic, and premium-looking.

| Industry | Main Use | Key Product Requirement |

|---|---|---|

| Food Processing | Packaging sauces, ready meals | Airtight, temperature-resistant |

| Retail & Supermarkets | On-shelf storage | Stackable, clear glass |

| Meal Prep & Delivery | Daily meal containers | Leak-proof, microwave safe |

| Restaurants & Catering | Back-of-house storage | Easy to clean, reusable |

When I work with meal-prep companies, they always want lightweight, portioned containers with tight lids. Supermarkets, however, prioritize visual appeal and stackability. Understanding your buyer type helps define what specifications matter most to your business.

Where Are the Best Procurement Channels to Buy Wholesale Glass Food Containers?

Choosing where to buy is one of the biggest decisions you’ll make. The wrong channel can waste months and money. The right one will give you control, reliability, and better margins.

You can source wholesale glass containers directly from manufacturers, through distributors, or via B2B platforms—each option has unique strengths and trade-offs.

Over the years, I’ve worked with buyers of all sizes—from supermarket chains to e-commerce startups. Their success often depends on picking the right channel for their capacity and goals. Below are the three most effective procurement paths I’ve seen.

1. Buying Directly from Glassware Manufacturers

Going factory-direct is ideal for established businesses and bulk orders. You get the lowest price and the most control. At PYGLASS, for example, we work directly with clients to design custom molds, create leak-proof lids, and print logos on containers. OEM/ODM flexibility gives you brand distinction that distributors can’t match.

However, direct sourcing means you manage more responsibility—international logistics, customs clearance 5{#ref-5}, and quality inspections. Minimum order quantities (MOQs) 6{#ref-6} are higher, and lead times can stretch to 45–60 days. But when done right, it builds a stronger brand foundation and cost advantage.

2. Working with Distributors or Suppliers

For smaller retailers or buyers testing new product lines, distributors are more practical. They hold local stock and can ship smaller quantities fast. This option is great for flexible restocking or seasonal promotions. You’ll pay a bit more per unit, but you save on logistics time and upfront inventory risk.

Distributors also simplify communication, often operating in your language and time zone. Still, you give up customization and rely on their stock availability. Always verify that they source from certified factories to avoid hidden quality risks.

3. Using Online B2B Marketplaces

B2B platforms like Alibaba 7{#ref-7}, Global Sources, and Made-in-China make supplier discovery easy. They’re perfect for market research and price comparison. But caution is key—not every “manufacturer” listed is a real factory. Always check business licenses, request certifications, and order samples before committing to a bulk order.

Here’s how these three sourcing paths compare:

| Channel | Best For | Advantages | Drawbacks |

|---|---|---|---|

| Manufacturer Direct | High-volume buyers | Lowest cost, full customization | High MOQ, longer lead time |

| Distributor/Supplier | Small to mid-sized buyers | Low MOQ, fast delivery | Higher cost, no customization |

| Online B2B Platform | Research & supplier discovery | Wide selection, easy comparison | Risk of resellers, requires vetting |

Selecting the right mix depends on your order volume, lead time needs, and brand strategy. Personally, I recommend starting small on a platform, then moving to direct sourcing once you verify product quality and build confidence.

How Should You Evaluate a Glass Food Container Supplier?

You’ve found potential suppliers—but how do you know they’re reliable? Fancy websites and low quotes mean nothing if products fail tests or shipments arrive late.

Always evaluate suppliers based on production capacity, certifications, sample quality, logistics reliability, and communication transparency.

When I vet new suppliers, I treat it like hiring a team member. You need to test their competence, integrity, and fit. Here’s the process I follow—and it’s saved me from many painful surprises.

Verifying Capabilities and Certifications

Start with the basics. Ask for factory size, production capacity, and number of lines. Request certifications: ISO9001 (quality system) 8{#ref-8}, FDA (US), LFGB (EU/Germany), and DGCCRF (France). A professional manufacturer will provide these freely. At PYGLASS, we also hold BSCI and Walmart audits—proof of ethical and reliable operations.

Never accept excuses like “we’re still applying.” That’s a red flag. It usually means they lack proper quality control or export experience.

Inspecting Sample Quality

A photo online can lie—but a sample can’t. Always order samples before confirming bulk production. I check for clarity, weight, smooth edges, and consistent sealing. For containers with lids, test the silicone ring. It should seal tightly but also remove easily for cleaning. I also test temperature resistance by moving samples from freezer to oven. If they survive, your customers will be safe too.

The sample reflects the factory’s real capability. If it fails, the bulk order will only be worse.

Communication, Logistics, and Support

A good product is useless if support is bad. Notice how fast and clearly a supplier replies. Do they answer questions directly or dodge details? At PYGLASS, every client has a dedicated account manager who follows production until delivery. We send inspection photos, packaging videos, and status updates.

Also, ask about their packaging standards. I always insist on multi-layer protection and drop tests before shipment. Good logistics means fewer damages and happier customers.

| Evaluation Area | What to Ask | What a Reliable Supplier Shows |

|---|---|---|

| Manufacturing | What’s your monthly output? | Transparent data, audit reports |

| Certifications | Can you share FDA/LFGB/ISO reports? | Valid, recent third-party reports |

| Samples | Are lids airtight and leak-proof? | Perfect sealing, clear glass |

| Communication | Who handles my order? | Fast replies, clear contact |

| Logistics | How do you prevent breakage? | Protective packaging, tested cartons |

Good suppliers don’t fear your questions—they welcome them. The right partner makes you feel informed and confident at every step.

Why Choose PYGLASS as Your Trusted Glass Container Manufacturer?

There are thousands of factories, but few you can truly rely on. Many promise quality, yet miss deadlines or skip safety tests. That’s why PYGLASS has become a long-term partner for over 50 global brands.

PYGLASS offers certified, customizable, and sustainable glass containers with proven reliability for global B2B buyers.

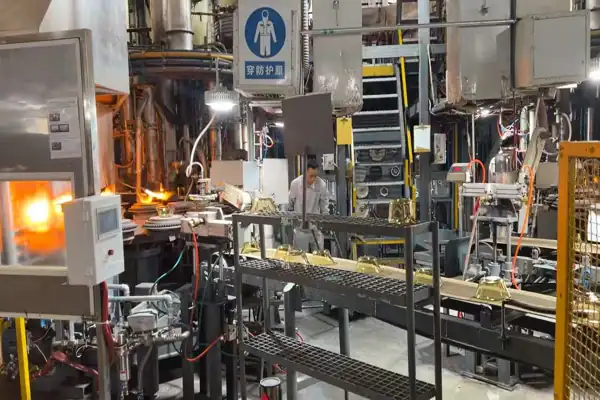

I founded PYGLASS after seeing too many buyers suffer from inconsistent suppliers. Our 200,000㎡ facility in Zibo, China, uses advanced automation for precision and consistency. Every container we produce meets international standards—ISO9001, FDA, LFGB, DGCCRF—and passes BSCI and Walmart audits.

Quality and Compliance You Can Trust

We use high-borosilicate glass 9{#ref-9}, a material known for its durability and thermal resistance. This glass can move safely from freezer to oven without cracking. Each batch undergoes full inspection before packing. We share third-party lab reports with clients because transparency builds trust.

OEM/ODM Customization and Branding

Your brand deserves unique products. Our in-house engineering team helps you design custom shapes, lids, and packaging. Whether you want a stackable set for supermarkets or leak-proof meal prep containers, we create it from concept to shipment.

We’ve helped major retailers launch top-selling product lines by combining functionality with design. Every customization is treated like a partnership—not just a project.

A Partnership Mindset

What sets PYGLASS apart is reliability. We understand that your deadlines are non-negotiable. Our project managers provide updates from production to shipment. We test packaging through vibration and drop simulations to ensure safe delivery.

We believe our success grows with yours. That’s why our slogan—Safer · Healthier · Greener—guides every decision we make.

| PYGLASS Advantage | Description |

|---|---|

| Manufacturing Scale | 200,000㎡ automated factory |

| Certifications | ISO9001, BSCI, FDA, LFGB, DGCCRF |

| Custom Services | OEM/ODM, packaging, logo printing |

| Export Experience | Over 100 brands across 3 continents |

| Sustainability | 100% recyclable borosilicate glass |

What Are the Best Practices for the Procurement Process?

Even with a great supplier, a weak process can create chaos. I’ve seen buyers lose money because they skipped key steps or relied on verbal promises.

Follow a clear procurement process—from research to long-term partnership—to avoid costly mistakes and delays.

Over time, I’ve refined a seven-step process that ensures smooth, predictable sourcing.

Step 1–3: From Planning to Sampling

It starts with research.

Step 1: Needs Analysis and Market Research. Define your exact product specs—sizes, materials, and budget. Study your competitors and market trends to ensure your offer stands out.

Step 2: Supplier Screening. Shortlist suppliers with valid certifications, strong communication, and positive reviews. Request RFQs and compare not just price but service level.

Step 3: Sample Testing. Never skip this. Test samples for sealing, transparency, and heat resistance. Approve only after full evaluation.

Step 4–5: Finalization and Quality Control

Step 4: Negotiation and Contract Signing. Put every term in writing—price, MOQ, payment schedule, and delivery date. Use clear incoterms like FOB or EXW 10{#ref-10}.

Step 5: Order Execution and Monitoring. Stay in contact during production. Ask for updates and inspection photos. For large orders, hire a third-party QC firm for mid and pre-shipment checks.

Step 6–7: Delivery and Long-Term Partnership

Step 6: Logistics and Receipt. Plan freight early. Confirm packaging meets your standards and get insurance for transport. Once the goods arrive, inspect them again.

Step 7: Building Long-Term Relationships. Share feedback and future plans with your supplier. The more they understand your business, the better they can serve you. Long-term trust leads to lower costs and higher reliability.

Conclusion

Buying wholesale glass food containers is not just about price—it’s about building a safe, reliable, and sustainable supply chain. Understanding the market, choosing the right procurement channel, and carefully vetting suppliers will save you time and protect your brand.

If you want a partner who delivers quality, compliance, and peace of mind, PYGLASS is ready to support your business. Together, we can make every meal safer, healthier, and greener.

Brand: PYGLASS — Safer · Healthier · Greener

www.slyprc.com

Footnotes

1. An overview from the UN Environment Programme on the global movement to combat plastic pollution. ↩︎

2. McKinsey report on how consumer demand for sustainable and healthy packaging is shaping the market. ↩︎

3. Mordor Intelligence report detailing the size, share, and growth trends of the glass container industry. ↩︎

4. An IMF analysis of how supply chain disruptions impact global trade and sourcing strategies. ↩︎

5. U.S. Customs and Border Protection guide on the basics of the import and export process. ↩︎

6. Investopedia explains Minimum Order Quantity (MOQ) and its importance in wholesale purchasing. ↩︎

7. Alibaba is a leading online B2B marketplace for sourcing products from global suppliers. ↩︎

8. The International Organization for Standardization explains the ISO 9001 standard for quality management systems. ↩︎

9. PYGLASS details the benefits of high-borosilicate glass for durable and safe food storage containers. ↩︎

10. The International Trade Administration provides a guide to Incoterms used in global trade contracts. ↩︎